There are basically three types of inkjet printers, Thermal Inkjet (TIJ), Continuous Inkjet (CIJ) and Drop on Demand Inkjet (DOD), all with their own key benefits and solutions to specific needs. Understanding the differences between them will help you determine which is best for your printing job.

Thermal Inkjet Printers (TIJ)

This type of printer has been developed to provide high quality printing coupled with high speed and flexibility in terms of the packing requirements. It is well established in its industry and is known to be reliable, maintenance free and overall clean printing job. In many industries it is used for numerous applications on both porous and non-porous surfaces.

If the printer is coupled with an offline feeding system it is a great match for the following:

- Printing serial identifications for the medical industry

- Printing dates on food sleeves

- Identification purposes and verification for the pharmaceutical industry

- Serialized coding of Tyvek® medical pouches, pharmaceutical labels and cartons

The overall benefits of this setup would be the combined print head and ink cartridge (think HP or Lexmark cartridges for desk top printers) making the setup virtually maintenance free along with exceptional quality of the print at a high speed rate creating a lot of flexibility depending the situation and job at hand.

Continuous Inkjet Printers (CIJ)

Different from the TIJ, the CIJ uses an electrically charged ink to create hi-resolution characters based on a specific formation. These printers can use a wide variety of ink and are easy to install and very versatile. Their uses involve printing text and graphic on just about any surface while creating a high quality print.

If the printer is coupled with an offline feeding system it is a great match for the following:

- Date coding of food sleeves.

- Carton coding of difficult substrates

The benefit is an extremely flexible printing application at high speed that is easily installed and has a huge variety of inks to match the material it is printing on.

Drop-On-Demand Inkjet Printers (DOD)

This printer type allows for a diverse printing ability from production dates on a wide variety of products to barcodes and they create hi-resolution images, which is ideal for graphics.

If the printer is coupled with an offline feeding system, similar to the CIJ, it is a great match for the following:

- Mailing and addressing applications.

- Commercial printing of plastic cards and business forms.

The benefit is an extremely flexible printing application and can print in a variety of ways, personalized to the needs of the user.

For more information about these printers, review our inkjet products or contact us for more information.

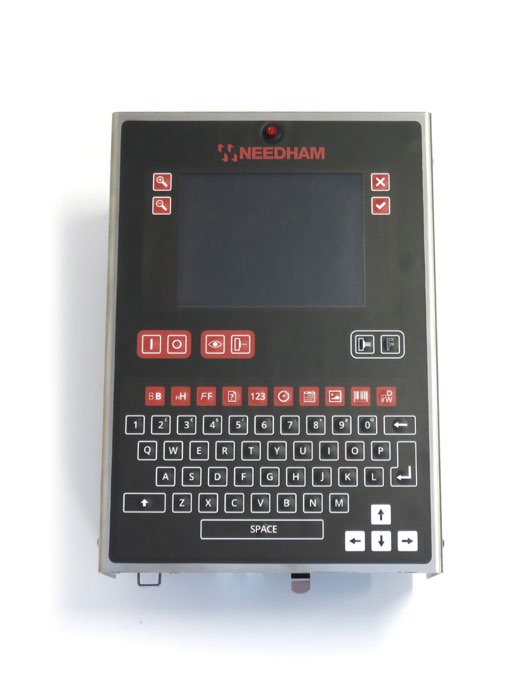

Foenix Printer Features The market is flooded with various models of ink jet printers across a wide range of technologies, brand names and ink types, which can make it challenging to discern what printer is the best for which application and environment. Many in the industrial and commercial marketplace are loyal to Foenix Coding Printers,...Continue reading→

Within the past year Griffin-Rutgers has noticed a dramatic rise in thermal inkjet coders over continuous inkjet (CIJ) within the food packaging industry for the variable information coding of its packaging. This is a result of the fact that thermal inkjet technology has seen huge advances in the recent years. In the past, the knock...Continue reading→

Over the past decade, designers of TIJ (Thermal inkjet) printers have worked tirelessly to address the limiting factors of the technology. The latest generation of TIJ printers will outperform CIJ (continuous inkjet) in terms of cost of ownership and print quality in most coding applications. Despite the discernible shift to TIJ, there’s still some outdated...Continue reading→

Compared to the traditional printing processes used in the printing of packaging such as flexography and offset lithography, inkjet as a primary method of package printing is relatively new. It’s also an area of growth and opportunity that did not go unnoticed at Drupa 2016, as many vendors focused on packaging solutions using digital inkjet...Continue reading→

Medical packaging, such as blister packs and Tyvek pouches, often require unique handling and inkjet printing systems, and it’s typically found that offline coding systems work best. An offline feeding and transport system helps to automate the printing process or can completely replace the need for a label by printing directly onto the packaging. What...Continue reading→

There are myriad options on the market when it comes to coding and marking of items but the device needs to suit the specific purpose and the items being marked or coded. To make an informed decision you need to understand some of the science behind the technology. One such technology, thermal inkjet (TIJ), was...Continue reading→

Coding and marking products and services for the packaging industry are versatile. Current technology allows you to print on nearly any type of packaging including foil, film, cartons, sleeves, packets, pouches, tubes, cables, lumber and more. Printers also provide the option of printing labels made of paper, plastic or vinyl. Flexible Film & Lid Stock...Continue reading→

Is your company in need of a new printer? Are you considering Inkjet Printers and Laser Printers? Check out this infographic to see how the two measure up to one another!...Continue reading→

Despite its misleading name, Web printers do not relate to the Internet either. Rather, web printers for blisters and pouches are specially designed pieces of equipment that print on what is known as web stock, web material or lid stock. These the materials are webbed together to make pouches or something that has a blister pack—the packaging where you push the tablet or product out through various types of coated and uncoated foils.Continue reading→

The plant and garden industries strive to provide valuable information for their customers to help maintain the beauty and life of all types of greenery. And, for green thumbs to benefit from the information, they need to be able to see it. This means that printing on plant trays plays an integral role because the process must ensure that the information stays put through all types of element-driven environments, often with direct exposure to sunlight, excess water, wind, etc. Enter the Sauven 6000R Plus—a machine noted for its ability to respond to the highly specialized needs of printing on plant trays.Continue reading→