Griffin-Rutgers offers labeling and coding systems that work particularly well within the automotive industry.

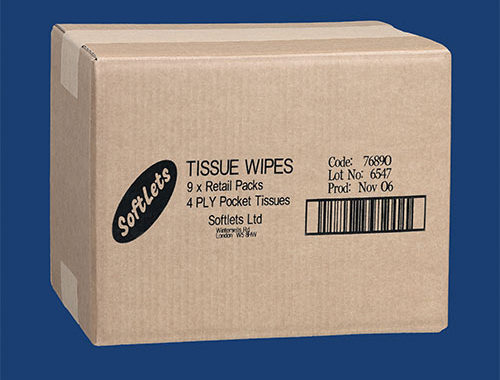

Automotive parts are packaged in many different ways. Often times parts come in trays, blister packs, or cardboard boxes. Each design has its own unique challenges.

For an automotive parts supplier, one thing that is worse than a faulty part is a faulty label. A misprinted digit, or a mislabeled part can mean costly recalls which can lead to lost business. Providing efficient tracking and tracing of shipped products enhances customer loyalty and your company image.

With this much riding on correct labeling, you need a solid solution to your label production process which will protect it from error-prone processes like manual data entry. A digitized labeling system is key component to the packaging line.

News

Tracking Auto Parts Items Through The Entire Supply Chain

Product recalls of consumer goods or automotive parts are news stories we hear about on a regular basis today. When there is a recall, chances are you hear not only about the item and the brand name, but also the location in which they were, manufactured, where they were sold, the expiration date, and, more […]

Plasticized PVC In The Automotive Industry

The average car today has more than 1,000 plastic components and roughly 12% of them are made of soft PVC. The main uses include underbody coatings and sealants, wire harnesses, synthetic leather for seats, passenger compartment parts and small exterior trims and fittings. Vehicle manufacturers clearly recognize the performance at both low and high temperature, the design, weight and cost […]

Mini Panel Labeling Advantages

The Mini-Panel labeling system is one of those technologies that continues to evolve. It currently offers the flexibility of using one or two labeling heads and can be used offline (semi-automatically) or can be integrated into a production line (fully automated). Many manufacturers might consider a mini labeling system to be an “entry level” device, […]

At Griffin-Rutgers we understand the never-ending demand for consistent, accurate labeling, along with the need for print clarity and product tracking mechanisms throughout the packaging and distribution chain. As you consider the purchase, we can help you determine the best product identification (labeling and coding) system for your unique needs. Contact the professionals at Griffin-Rutgers, and we will put our experience to work to select the exact system for you.

Products

Re-Pack Mini Wrap Labeling System (Table Top Model)

Designed to fill the gap between semi-automatic labeling machines and complete wrap systems

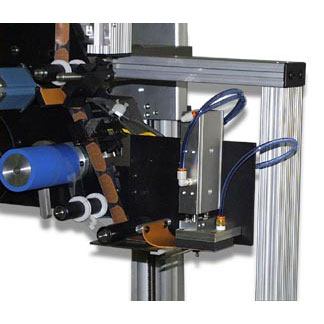

Re-Pack APT Print and Apply Labeling Head

Developed to fill the void between table top printers and print engine based Printer/Applicators

S-7000 Trio and Quatro

The S-7000 Trio and Quatro are ideal for high resolution printing directly onto cartons, trays and sacks, with a printing heights of up to 50mm or 67mm respectively.

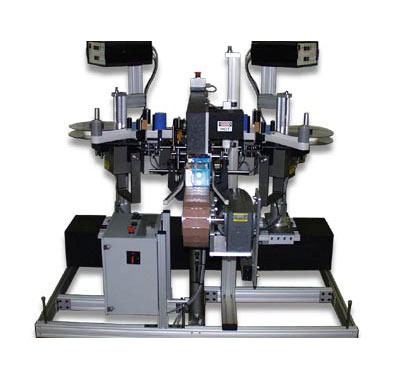

Re-Pack Top Panel Labeling System With Bag Feeding Device

Pick & place feeder, conveyor, series 4 stepper driven labeling head