The food and beverage industry covers a wide variety of items; snacks, candies, baked goods, all types of packaged meats, dairy, and many types of beverages are all included.

At Griffin Rutgers, we understand the importance of excellent print quality and ensuring operational goals are met. We offer the perfect combination of technology, expertise and service options when it comes to your choice for printing and coding on a wide range of packaging materials used within the food and beverage industry.

The Food and Drug Administration (FDA) is responsible for assuring that all foods and beverages sold in the United States are safe and properly labeled. As a result, it is imperative that labeling and coding systems can be changed seamlessly when new labeling regulations are required.

It’s important that your packaging meets the demands of the ever-changing industry and its regulations. At Griffin-Rutgers, we have a solution to meet your labeling and coding requirements. Contact us and we will put our experience to work to select the precise system to meet your needs.

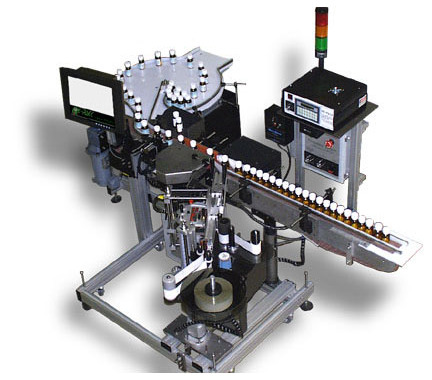

Re-Pack Top & Bottom Labeling System With Side Hugger Belts

Hugger belts capture the product from both sides, leaving the top and bottom of the container exposed for label application

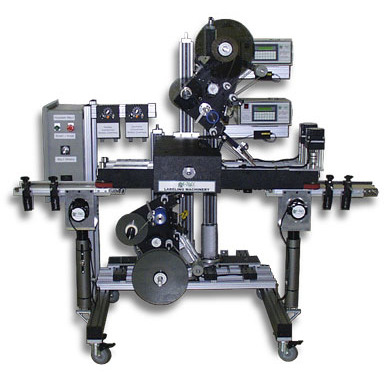

Re-Pack Dual Label Roll Unwind System with Splicing Table

Dual powered unwinds for high speed label applications providing a continuous supply of labels

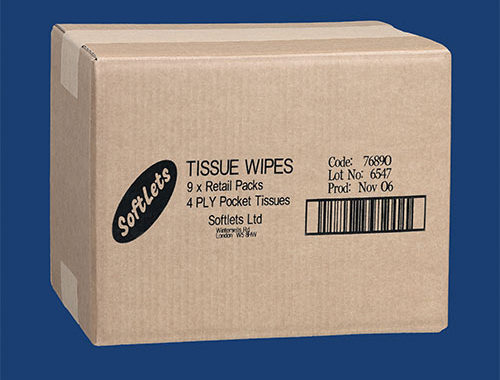

Re-Pack Mini Top Labeling System

Apply labels to the top panel of flat products such as bags and boxes

S-7000 Trio and Quatro

The S-7000 Trio and Quatro are ideal for high resolution printing directly onto cartons, trays and sacks, with a printing heights of up to 50mm or 67mm respectively.

Rotech RF1

Vacuum transport system using either thermal ink, jet, thermal transfer , hot stamp or laser coding systems

Do you need to print a product identification code directly on to a bread bag? Code a lot number and expiry date on a cake or donut carton? Place a label, pre-printed or printed in-line, on a clamshell of sliced pound cake? Identify a case of whole wheat pitas with manufacturing date, expiry date, batch code and bar code or more? Put a unit and sale price on a bag lock tag? We at Griffin-Rutgers offer the solutions for all of these applications with cost-efficient, easy to operate and maintain, printing, coding and labeling systems.

What Must Be On A Food Label?

When it comes to the food industry relative to what must be on a food label, there are very specific guidelines that dictate decisions concerning food packaging and label design and production. The foremost entity that determines what must be on a food label is the U.S. Food and Drug Administration (FDA) as they are the governing body that enacts and enforces such decisions.

Food Packaging Trends in 2018

Food packaging developments, sustainability and packaging design trends lead as top issues so far this year in this ever-growing business. Griffin-Rutgers offers coding and printing equipment to deliver high-quality coding for your food packaging needs. Here’s a look at the current food packaging trends in 2018.

Creating Authentic Food Labeling

According to a study conducted by OnePoll, 75% of those who responded, noted that if the term ‘organic’ was used on the label or in the marketing campaign, they were more likely to make a purchase of said item. Nearly 60% were attracted to any given item if it was labeled ‘all natural’. The survey also found that roughly 20% of the respondents have full trust in organic food labels, with less than 60% having only partial trust.

Mini Panel Labeling Advantages

The Mini-Panel labeling system is one of those technologies that continues to evolve. It currently offers the flexibility of using one or two labeling heads and can be used offline (semi-automatically) or can be integrated into a production line (fully automated). Many manufacturers might consider a mini labeling system to be an “entry level” device, […]

Printing and Coding Salty Snack Packages

Impulse purchases of consumers are what causes snack companies to be in heavy competition, and capturing sales means making the most of their brands. Before that bag of chips ever gets to the shelf, and entire team of brand marketers are working to maximize the packaging artwork for marketing and promotional purposes. The last thing […]

3 Tips for Food Labeling on Plastic Bags

Food labeling involves taking into account many specific U.S. Food and Drug Administration (FDA)-driven rules and regulations to ensure accurate and complete information is presented to the consumer when making a purchase decision. With a glut of food recalls or incidences of food production-related illness and death in recent years, food labeling is a serious matter that’s central to a food manufacturing strategy.

Organic Baby Food Packaging

Not only is organic baby food evolving, but, the packaging of said products continues to change with market demands. Gone are the days when mothers and fathers just grab a jar of baby food for their youngster without any question to the ingredients or packaging. The top four emerging trends driving the global baby food […]

Horizontal Packaging Needs

Improvements in technology are seen everywhere in the workforce and in consumer products and packaging. Laptop computers that used to be rather weighty now seem featherweight. Innovations in packaging also continues to grow at a steady pace. The automation of horizontal packaging allows your business to run at a more efficient rate and be able […]

GMO Labeling Requirements to Change

An argument over the need to identify food products that include genetically modified ingredients (GMI or GMO) has been ongoing for years as such products so modified have been entering our food supply over the last two decades. Yet, it may still come as a surprise to many consumers that a great number of products […]

Food Labeling on Fruit: 5 Things to Consider

Even natural, perishable foods need to undertake rigorous food labeling when it is sold to consumers through grocery stores, markets, and other retail operations. Even if is obvious that the ingredient is a banana or an apple, there are some things to consider when it comes to food labeling on fruit.