At Griffin-Rutgers, we understand that the manufacturing environment is harsh. When faced with unique labeling requirements, and critical applications are part of the equation, we are here to help simplify the process.

The manufacturing industry covers a wide variety of applications such as injection molding, flexible packaging, and piping. Each of these sectors faces unique labeling challenges that requires strength and durability. By treating labeling as a strategic part of the process, companies throughout the manufacturing supply chain are able to make shipments more traceable, achieve consistent branding, reduce regulatory costs, eliminate data redundancy, and improve overall labeling efficiencies. The correct labeling solution lets you turn labeling into a high-value, strategic element of the overall manufacturing and distribution process.

Dalemark Series 25 – Handi-Coda

This is absolutely the simplest and most cost efficient way to code cartons, cases or trays, or other flat goods made of absorbent materials. It can be used to code on formed or flat goods. It is perfect for small runs or for moving between packaging lines. It is absolutely simple to operate as the […]

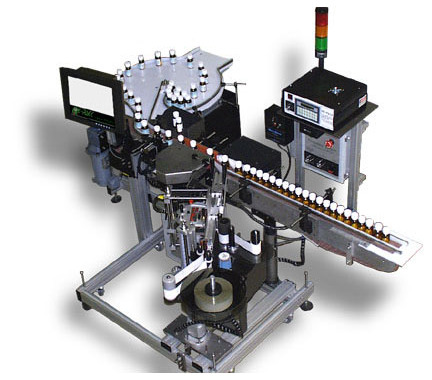

Re-Pack Accutrak Side Panel Labeling System

Includes a product conveyor, a top stabilizer, and a label applicator – Additional features such as infeed timing screws, wrap stations, and inspections systems

Re-Pack Three Roller Indexing Labeling System

Designed to orient the product and apply a wrap around label registered to this orientation point

Dalemark Series 100 Carton Coder

This simple coding device is designed to integrate with a conveyor transporting cartons, cases or trays. Models are available that can print either registered print in precise locations or random repeating messages. It can print on the top, side or bottom of moving packages. By using quickly interchangeable rubber type characters it produces sharp, dark, […]

Re-Pack Mini Wrap Labeling System (Table Top Model)

Designed to fill the gap between semi-automatic labeling machines and complete wrap systems

Markoprint X2Jet

HP or LX print system with onboard label creation and editing. Runs 2 HP or LX print heads

In today’s complex and challenging manufacturing supply chain environments, forward-looking companies are increasingly taking a more strategic approach to labeling. At Griffin-Rutgers we understand the never-ending demand for consistent, accurate labeling, along with the need for print clarity and product tracking mechanisms throughout the packaging and distribution chain. As you consider the purchase, we can help you determine the best product identification (labeling and coding) system for your unique needs. Contact the professionals at Griffin-Rutgers, and we will put our experience to work and help you select the exact system for you.

Why Pay More for a Thermal Transfer Overprinter (TTO)?

Since the inception of thermal transfer overprinters (TTOs) in the early 1990’s, Griffin-Rutgers has been there. That’s why we know that all TTOs function in the same manner, based on the identical operating principles – energize the print head, heat the ink on the mylar carrier, and with a little head pressure leave an image […]

Markoprint iJet

The Markoprint product line, including the iJet shown here, brings Intelligent print systems for industry applications. High performance data management equals high speeds of up to 80 variable codes per second. Solutions offered for splash water and harsh environmental conditions.

Five Product Packaging Fundamentals

When it’s time to create the perfect packaging for your product, there are many choices that need to be made. The packaging should be attractive, while complying with many regulations regarding the content. It should also reinforce your company’s brand.

Food Packaging Trends in 2018

Food packaging developments, sustainability and packaging design trends lead as top issues so far this year in this ever-growing business. Griffin-Rutgers offers coding and printing equipment to deliver high-quality coding for your food packaging needs. Here’s a look at the current food packaging trends in 2018.

Digital Thermal Transfer Printing on Cardboard

When it comes to tracking down the best systems for digital thermal transfer printing on cardboard, there are a number of options to choose from based on specific applications and operational environments. Listed below are two of the leading-edge solutions in the marketplace today for digital thermal transfer printing on cardboard.

Introducing the Bell-Mark EasyPrint ECO: Low Consumption, High Efficiency, Thermal Transfer Coder

Griffin Rutgers presents the EasyPrint ECO- low consumption, high efficiency, thermal transfer coder. Print high resolution images directly on all types of packaging material such as flexible film and labels. Create text images up to 8 lines high using 6 customizable font types and 7 different font sizes

5 Efficient Packaging Tips

If your role is as a brand manager, production or plant manager, then you know your primary focus includes the bottom line. Packaging affects many different parts of your product line, which in turn drives the growth of your business. Cost reduction and revenue growth can be tied directly to the way you package and […]