Many businesses print their own logo, bar codes, and packaging information onto bags, whether film or poly, as it can be more cost effective than buying them in bulk already printed. Printing your own bags gives you greater control when you need to change dates, UPC codes, or even print some to advertise a particular promotion. We offer a variety of printers to meet your needs.

This is a small sample of the products we offer which can print and code on Bags and Films and Poly Bag Substrates:

FlexPackPRO® XT Series with Large Ribbon Capacity

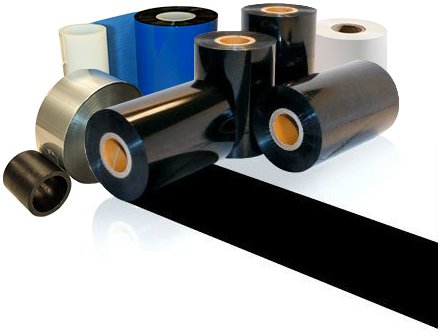

Thermal Transfer Overprinters, ribbon rolls up to 1000 meters

Griffin Rutgers: Bags and Films and Poly Bag Substrates

Offline Coding Leads To Compliance

Pharmaceutical manufacturers and packagers could be facing increased costs due to re-engineering of production lines to satisfy newly upgraded European Union Falsified Medicines Directives (FMD). Printing and packaging systems that carry out coding, and its related post-print inspection, offline as an independent process might make it easier for manufacturers to meet the new compliance requirements […]

3 Creative Ideas For A Unique Display Label

Product purveyors know that a display label is critical for attracting customers to an item on retail shelves. The label must stand out to get the necessary attention amongst all the other competitive products crammed in around, above, and below the product. That’s why it is well worth the time and effort to create a unique packaging label that draws attention and ultimately facilitates your product being selected above and beyond all others on the shelves. Here are a few tips and tricks on what to focus on to create a unique display label, which, of course, must also contain pertinent information like product information and pricing.

Labeling Machinery for Tapered Containers from Griffin-Rutgers

This label applicator is designed to wrap labels around tapered containers. The application requires that a “Banana cut” style label is used to match the taper of the container. We have overcome the label skew issue by partially pre-dispensing the label and finishing the application at

Packaging, Printing & Labeling Snacks

Consumers want snack packaging that is easy to open, keeps products fresh, and is easy and convenient to take on-the-go.

Designing a Display Label: 4 Elements to Consider

When it comes to a display label, there are some very specific elements that you must consider when creating a design that stands out on the shelf and garners the attention you are seeking from your target customer. Here are some important elements that you will want to consider in your design.

Using Modern Technology In The Pharmaceutical Industry

With the advances in technology, most industries have jumped on board to ensure that their labels, packaging, tracking system, marketing, etc., is relying on new and improved ways to keep their operations running smoothly. Using modern technology in the pharmaceutical industry is helping lower the chances of errors in medical offices, hospitals, nursing homes, etc., […]

High Resolution Printing: Features Of The Foenix FXONE-Touch

Whether you’re a first year start-up, a larger company that has only a small need for high resolution printing or a company that has a large need for high resolution printing there’s a good chance you’re looking for a low-cost way to code your packages. But, of course, you still want to look professional in […]

How Traceable Are Your Meal Sleeves?

Prepared foods sometimes get a bad rap, but for the busy family or professional, ready to eat meals and prepared foods can certainly be a viable and healthy option. The market has continued to grow steadily, in part because of consumer demand. Food packagers that produce these meals in high volume find that an automated […]

Pharmaceutical Labeling Requires Specialized Printers

Manufacturers and packagers of pharmaceutical products understand that a product identification system for pharmaceutical packaging requires two separate, but highly integrated components. It is mandatory to have a labeling system that can consistently apply labels at the required speed and with a high degree of accuracy. Along with such a labeler packagers need a print […]

Food Labeling on Fruit: 5 Things to Consider

Even natural, perishable foods need to undertake rigorous food labeling when it is sold to consumers through grocery stores, markets, and other retail operations. Even if is obvious that the ingredient is a banana or an apple, there are some things to consider when it comes to food labeling on fruit.