Thermal Ink Jet

High quality, high speed and flexible coding options are three of the reasons that thermal inkjet printers (TIJ) are typically chosen for use in the packaging industry. This technology provides a clean print, is reliable and is virtually maintenance free. Thermal inkjet printers can be used in industrial applications that require printing on both porous and non-porous items.

TIJ technology can house up to eight individually functional print heads that are operated by one controller and this allows for multiple print positions on a single package – especially useful when printing large size items – or packages spread over up to four production lines. If a user couples the TIJ with an automatic offline feeding system, the printer is then ideal for use:

- In the pharmaceutical industry for finely printed product identification and verification information

- In applying date codes to food sleeves

- And for coding of items that are packaged in medical pouches

Because these printers offer a combined print head, fully contained ink cartridges and virtually zero maintenance they are sought after in many industries for their cleanliness and simplicity of operation.

A second type of inkjet printer is a continuous inkjet (CIJ) model which is operated by using “electrically charged ink droplets” that provide very high speed printing and instantly dry inks. These printers use a wide variety of inks developed specifically for them. These printers are considered highly versatile, and are capable of printing both text, codes, and simple graphics onto almost any surface.

A third inkjet technology, the piezoelectric drop on demand inkjet (DOD) printer is used for printing barcodes, expiration dates, production dates and batch identification information in industrial settings and can often replace the use of labels on cases. They provide high print resolution, large print characters and simple printing flexibility.

Understanding the amount of printing required and the type of surface to be printed are the first steps toward knowing what type of printer will fulfill your unique coding or printing needs.

Foenix Printer Features The market is flooded with various models of ink jet printers across a wide range of technologies, brand names and ink types, which can make it challenging to discern what printer is the best for which application and environment. Many in the industrial and commercial marketplace are loyal to Foenix Coding Printers,...Continue reading→

Within the past year Griffin-Rutgers has noticed a dramatic rise in thermal inkjet coders over continuous inkjet (CIJ) within the food packaging industry for the variable information coding of its packaging. This is a result of the fact that thermal inkjet technology has seen huge advances in the recent years. In the past, the knock...Continue reading→

When it comes to selecting a printer to code or mark variable information onto your packaging or product, reliability is crucial. TIJ printers offer that reliability. They are simple and maintenance-free, making them the perfect fit for your coding and packaging needs.

Over the past decade, designers of TIJ (Thermal inkjet) printers have worked tirelessly to address the limiting factors of the technology. The latest generation of TIJ printers will outperform CIJ (continuous inkjet) in terms of cost of ownership and print quality in most coding applications. Despite the discernible shift to TIJ, there’s still some outdated...Continue reading→

Compared to the traditional printing processes used in the printing of packaging such as flexography and offset lithography, inkjet as a primary method of package printing is relatively new. It’s also an area of growth and opportunity that did not go unnoticed at Drupa 2016, as many vendors focused on packaging solutions using digital inkjet...Continue reading→

Selecting a printer for your needs can be challenging as the world of printers is vast with any number of features, gadgets, and prices. Known as a global leader in ink jet printers with a reputation of quality and reliability, UK-based Needham Printers deliver even more in terms of benefits designed to meet your business objectives. Continue reading→

At the start of the decade, QR codes began to make an appearance on almost all forms of packaging. However, if you used them for your packaging solutions back then, you probably hated them. In the beginning, the end-users had terrible experience using QR codes. They are now on the rise in many forms of...Continue reading→

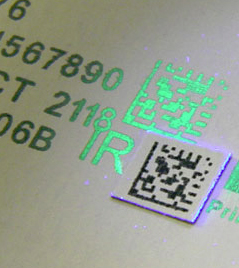

It seems impossible, but the use of printed codes on packaging continues to increase. They seem to be everywhere, on everything. Now, you can add prescription drug anti-counterfeiting measures to the list. With more requirements being set, manufacturers must ensure that they are printing codes on prescription drug packages to meet the more stringent standards.Continue reading→

When seeking a top-performing printer that can effectively deliver quality coding and printing on corrugated boxes, cases and trays, look no further than the Needham S-6000Plus. This best-of-breed ink jet machine utilizes the latest technology to provide online, high resolution capabilities that work for everything from small and large characters to bar codes and graphics. Continue reading→

The plant and garden industries strive to provide valuable information for their customers to help maintain the beauty and life of all types of greenery. And, for green thumbs to benefit from the information, they need to be able to see it. This means that printing on plant trays plays an integral role because the...Continue reading→