In the past several years, a few states have passed new laws in regards to medical marijuana being a choice for people in their states looking for alternative medicine.

Regardless of what anyone might think of the cannabis industry, marijuana is making progress at becoming legal and is on the verge of becoming a mainstream industry, both for medical and for personal use.

It’s important to note that even within this niche of the pharmaceutical industry, your packaging and coding is just as crucial as it is with other medications. Proper cannabis labeling and packaging is an important component to staying in compliance with state guidelines. Cannabis companies must ensure that their packages are tamper-proof, child-proof, and within accordance of their local laws.

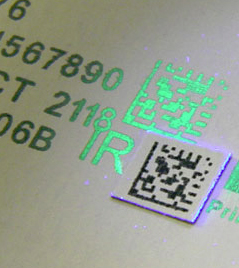

Most states require date and lot coding (as well as other information in many cases) to be printed on the packaging that is used for marijuana products, whether intended for personal or medical use.

For instance, the laws in Arizona differ from the laws in Colorado. As each state is regulating their own portion of the industry, and it cannot be shipped out of each individual state, keeping up on the regulations in your state is extremely important. As these regulations can change rapidly as the industry grows, staying on top of those changes, and adjusting your equipment to those specifications, will keep your packaging running smoothly.

At Griffin Rutgers, we offer specific labeling and coding (marking) equipment that will help keep your operation running on target with each state in which you operate.

For instance, we offer thermal ink-jet industrial printers for in-house installation to ensure that your packaging is printed in accordance with your local laws. Having the thermal ink-jet within your operation, will not only cut down on errors, but, will also reduce turnaround time.

Also, as stated in the laws of Colorado: (not inclusive)

A producer shall label each marijuana product prior to sale to a dispensary and shall securely affix to the package a label that states in legible English:

- The name and address of the producer;

- The brand name of the marijuana product that was registered with the department;

- A unique serial number that will match the product with a producer batch and lot number so as to facilitate any warnings or recalls the department or producer deem appropriate;

- The date of final testing and packaging;

- The expiration date;

- The quantity of marijuana contained therein;

With the amount of information that needs to be on the labels in Colorado alone, one of our Print & Apply Labeling Systems may also be a good choice for your operation.

We are here to consult with your team and get your facility in 100% compliance with your states packaging regulations.

The number of babies expected to be born in the next year is less than usual due to the coronavirus problem. However, there are still many babies who need baby bottles and nipples to fulfill their feeding needs.Continue reading→

Child-resistant (C-R) packaging, also referred to as "special packaging," is used to reduce the risk of poisoning in children via the ingestion of potentially hazardous items including certain prescription and over the counter (OTC) medications, pesticides, and household chemicals.Continue reading→

In 2018, product packaging gave manufacturers a lot of innovative ideas and options, both functionally and aesthetically. 2019 promises to be just as innovative, and continue to grow with more color, graphics and material in exciting new ways.Continue reading→

If your role is as a brand manager, production or plant manager, then you know your primary focus includes the bottom line. Packaging affects many different parts of your product line, which in turn drives the growth of your business. Cost reduction and revenue growth can be tied directly to the way you package and...Continue reading→

The food and medical industry seem to change and grow daily. With that, comes stricter package labeling being required by the FDA. It’s important that your packaging meets the demands of the ever-changing industry and its regulations. At Griffin-Rutgers, we have a solution to meet your labeling requirements.

It seems impossible, but the use of printed codes on packaging continues to increase. They seem to be everywhere, on everything. Now, you can add prescription drug anti-counterfeiting measures to the list. With more requirements being set, manufacturers must ensure that they are printing codes on prescription drug packages to meet the more stringent standards.Continue reading→

Improvements in technology are seen everywhere in the workforce and in consumer products and packaging. Laptop computers that used to be rather weighty now seem featherweight. Innovations in packaging also continues to grow at a steady pace. The automation of horizontal packaging allows your business to run at a more efficient rate and be able...Continue reading→

This article possibly should be titled, “Getting to the bottom of your product is a challenge.” It’s overly simplified to say the bottom of something is the bottom because it’s standing on that surface, but that’s exactly the problem – access. Bottom labeling, or coding, requires clear access to the bottom. That’s it. Systems for...Continue reading→

To order labels or to print labels is a question that many business owners wrestle with, especially when they’re first starting out. For many businesses the answer ends up being, “it’s better, less expensive and faster” to print their own labels. Why should you print your own? The printing professionals from Griffin-Rutgers offer these reasons...Continue reading→

The Mini-Panel labeling system is one of those technologies that continues to evolve. It currently offers the flexibility of using one or two labeling heads and can be used offline (semi-automatically) or can be integrated into a production line (fully automated). Many manufacturers might consider a mini labeling system to be an “entry level” device,...Continue reading→