With the package coding industry becoming ever-competitive and specialized, it is important to examine all methods to discern what is best for your business. Toward this end, computer generated stencil printing is a method that should not be overlooked. Here we’ve provided an overview of what computer generated stencil printing can do, basic capabilities of this type of equipment, and costs to help you determine if this method will help realize your package printing objectives.

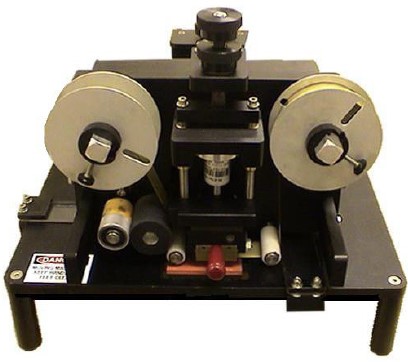

What is Computer Generated Stencil Printing? This is a printing process that takes a computer image, transfers that image to a film, and creates a stencil of that image on the film. The substrate used is primarily corrugated cases, which is moved between a print cylinder and an impression roller in order to transfer the image onto this substrate. The process of burning a stencil and mounting it on the cylinder takes less than seven minutes. Clean-up and maintenance is easy and waste is reduced.

What Does it Work Best For?

- This is an ideal process in terms of cost savings versus using pre-printed corrugated cases, kraft bags, or labels, especially if these labels are then added by hand.

- It is good for short print runs or frequently changing projects, including contract packaging or private labeling, found in an in-demand print environment.

What Type of Capabilities Does it Offer?

- With the help of a re-stacker, this process can print two case panels at the same time.

- Thanks to the integration of an inkjet coder, the system can accommodate variable coding.

- The speed averages 60 cases per minute while the stencil film can last through approximately 5,000 impressions.

- With the assistance of an automatic bundle inverter/inserter and a second printing system, faster production times can be achieved.

How Much Does it Cost? The costs vary with equipment costs for full carton printing, ranging from $39,000 to $70,000 while the operating costs for two-panel printing are $0.02 per case, on average. In Summary The main points in this blog post are:

- Computer Generated Stencil Printing transfers a computer image onto a film to create a stencil that is then applied and re-applied to substrates that are primarily corrugated cases.

- This is an ideal process in terms of cost savings versus using pre-printed corrugated cases, kraft bags, or labels, especially if these labels are then added by hand.

- The capabilities of the process can be enhanced by other equipment with the stencil printing, including a re-stacker, inkjet coder, and/or an automatic bundle inverter/inserter and secondary printing system.

- Costs vary, depending on the functionality needed.

Foenix Printer Features The market is flooded with various models of ink jet printers across a wide range of technologies, brand names and ink types, which can make it challenging to discern what printer is the best for which application and environment. Many in the industrial and commercial marketplace are loyal to Foenix Coding Printers,...Continue reading→

Within the past year Griffin-Rutgers has noticed a dramatic rise in thermal inkjet coders over continuous inkjet (CIJ) within the food packaging industry for the variable information coding of its packaging. This is a result of the fact that thermal inkjet technology has seen huge advances in the recent years. In the past, the knock...Continue reading→

Over the past decade, designers of TIJ (Thermal inkjet) printers have worked tirelessly to address the limiting factors of the technology. The latest generation of TIJ printers will outperform CIJ (continuous inkjet) in terms of cost of ownership and print quality in most coding applications. Despite the discernible shift to TIJ, there’s still some outdated...Continue reading→

Compared to the traditional printing processes used in the printing of packaging such as flexography and offset lithography, inkjet as a primary method of package printing is relatively new. It’s also an area of growth and opportunity that did not go unnoticed at Drupa 2016, as many vendors focused on packaging solutions using digital inkjet...Continue reading→

Needham Coding is a leading global manufacturer and supplier of state-of-the-art high resolution ink jet printers for the packaging industry. For almost 60-years, Needham Coding has been on the cutting edge of package identification, now using its own research and development department to advance ink jet technologies. Indeed, the company’s line of printers are revered...Continue reading→

If you are printing best-before or other fixed or variable information onto sleeves, pouches or cartons, an offline feed and coding system could be just what you need.

There are basically three types of inkjet printers, Thermal Inkjet (TIJ), Continuous Inkjet (CIJ) and Drop on Demand Inkjet (DOD), all with their own key benefits and solutions to specific needs. Understanding the differences between them will help you determine which is best for your printing job. Thermal Inkjet Printers (TIJ) This type of printer...Continue reading→

Medical packaging, such as blister packs and Tyvek pouches, often require unique handling and inkjet printing systems, and it’s typically found that offline coding systems work best. An offline feeding and transport system helps to automate the printing process or can completely replace the need for a label by printing directly onto the packaging. What...Continue reading→

There are myriad options on the market when it comes to coding and marking of items but the device needs to suit the specific purpose and the items being marked or coded. To make an informed decision you need to understand some of the science behind the technology. One such technology, thermal inkjet (TIJ), was...Continue reading→

Coding and marking products and services for the packaging industry are versatile. Current technology allows you to print on nearly any type of packaging including foil, film, cartons, sleeves, packets, pouches, tubes, cables, lumber and more. Printers also provide the option of printing labels made of paper, plastic or vinyl. Flexible Film & Lid Stock...Continue reading→