Two of the primary printing systems today are the inkjet and laser method. However, despite their popularity, many are still don’t know the difference between inkjet vs. laser systems and, hence, are unsure which they should choose for their application. When weighing inkjet vs laser systems, there are some specific attributes of each that will readily clarify which type of printer is right for your business. First, it’s important to know what each type of machine is capable of delivering. Here is an at-a-glance chart that matches up each printer type on a few specific factors of note:

Capabilities:

- Inkjet- Works well with products that transport at a continuous fixed speed motion; works fast; easy set-up and operation. There are a few types of inkjet printers, including thermal and continuous inkjet systems; capable of using a wide range of inks, including solvent-based, thermographic, UV-sensitive and UV-durable.

- Laser- It’s easy to operate and operates at top speeds; integrates well with the rest of the packaging line thanks to speed sensing shaft encoders.

Issues:

- Inkjet- Some environmental concerns.

- Laser- Can require a fume extractor to cut down on environmental and working condition issues.

Use Of Consumables:

- Inkjet- Use of inks and other consumables.

- Laser- Doesn’t use consumables.

Cost:

- Inkjet- Fairly low upfront cost but higher cost of consumables.

- Laser- Expensive upfront costs but no consumable costs and low maintenance costs.

Maintenance:

- Inkjet- New technology is reducing the need for maintenance.

- Laser- Relatively low unless it is in an environment where there is dust, moisture, or vibration.

Life:

- Inkjet- Average life.

- Laser- Long life up to 10 years.

Primary Applications:

- Inkjet- Primary and distribution packaging applications.

- Laser- Excellent choice when permanent marking is needed; support both continuous and intermittent package motion processes.

Of course, both types of machines are continually realize innovation as manufacturers continue to pursue the use of technology to further the capabilities and value of each. This is why it’s important to research each type of equipment before deciding on inkjet vs laser systems to ensure that you have addressed all the specific and unique needs of your operation using the most up-to-date information possible. In Summary These are the main points found in this blog post:

- Both inkjet and laser printing systems have their advantages and issues, which have to be weighed against individual factors that are important to your particular business objectives.

- Other factors that must be considered include use of consumables, cost, maintenance, life and primary applications.

- Each machine must be able to tick off as many boxes as possible for your business needs before you make an investment to ensure that you can meet productivity, quality, and volume goals.

Whether you’re a first year start-up, a larger company that has only a small need for high resolution printing or a company that has a large need for high resolution printing there’s a good chance you’re looking for a low-cost way to code your packages. But, of course, you still want to look professional in...Continue reading→

Foenix Printer Features The market is flooded with various models of ink jet printers across a wide range of technologies, brand names and ink types, which can make it challenging to discern what printer is the best for which application and environment. Many in the industrial and commercial marketplace are loyal to Foenix Coding Printers,...Continue reading→

Within the past year Griffin-Rutgers has noticed a dramatic rise in thermal inkjet coders over continuous inkjet (CIJ) within the food packaging industry for the variable information coding of its packaging. This is a result of the fact that thermal inkjet technology has seen huge advances in the recent years. In the past, the knock...Continue reading→

Over the past decade, designers of TIJ (Thermal inkjet) printers have worked tirelessly to address the limiting factors of the technology. The latest generation of TIJ printers will outperform CIJ (continuous inkjet) in terms of cost of ownership and print quality in most coding applications. Despite the discernible shift to TIJ, there’s still some outdated...Continue reading→

Compared to the traditional printing processes used in the printing of packaging such as flexography and offset lithography, inkjet as a primary method of package printing is relatively new. It’s also an area of growth and opportunity that did not go unnoticed at Drupa 2016, as many vendors focused on packaging solutions using digital inkjet...Continue reading→

Impulse purchases of consumers are what causes snack companies to be in heavy competition, and capturing sales means making the most of their brands. Before that bag of chips ever gets to the shelf, and entire team of brand marketers are working to maximize the packaging artwork for marketing and promotional purposes. The last thing...Continue reading→

The Needham S-6000 series is a great alternative to CIJ (Continuous Ink Jet) due to its ease of use and simplified maintenance benefits.Continue reading→

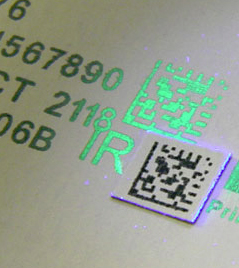

It seems impossible, but the use of printed codes on packaging continues to increase. They seem to be everywhere, on everything. Now, you can add prescription drug anti-counterfeiting measures to the list. With more requirements being set, manufacturers must ensure that they are printing codes on prescription drug packages to meet the more stringent standards.Continue reading→

This article possibly should be titled, “Getting to the bottom of your product is a challenge.” It’s overly simplified to say the bottom of something is the bottom because it’s standing on that surface, but that’s exactly the problem – access. Bottom labeling, or coding, requires clear access to the bottom. That’s it. Systems for...Continue reading→

By the time you purchase medicine at the pharmacy, it has gone through a rigorous amount of quality control for both the medicine and its packaging. Manufacturers, when using the proper pharmaceutical coding, labeling and packaging technology can track individual lots of medications throughout the supply chain from point of origin to point of sale....Continue reading→