Many businesses print their own logo, bar codes, and packaging information onto bags, whether film or poly, as it can be more cost effective than buying them in bulk already printed. Printing your own bags gives you greater control when you need to change dates, UPC codes, or even print some to advertise a particular promotion. We offer a variety of printers to meet your needs.

This is a small sample of the products we offer which can print and code on Bags and Films and Poly Bag Substrates:

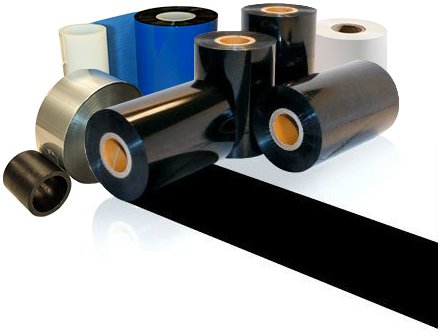

FlexPackPRO® XT Series with Large Ribbon Capacity

Thermal Transfer Overprinters, ribbon rolls up to 1000 meters

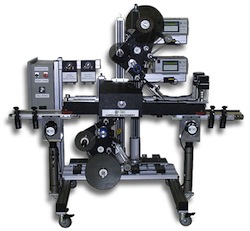

Griffin Rutgers: Bags and Films and Poly Bag Substrates

Three Panel Labelers and Three Panel Print & Apply Labelers for All Products & Containers

Three panel label applications on square and rectangular cases have become common place and we offer a line of labeling machines specifically for these applications. We even have a machine that can quickly be changed over from 3 panel to single panel or wrap label application. Labeling applicators are great for boxes and cartons, round […]

The Benefits of an Indexing Starwheel Labeling System

The Indexing Starwheel Labeling system manufactured by Re-Pack is one that is designed to easily integrate with an existing conveyor line system. An indexing system such as this is normally used when a label needs to be placed on the bottom of a container after the filling and capping stations. Containers such as jars, tubes, […]

Top and Bottom Labeling Systems Defined

If you’ve ever wondered “what is a top and bottom labeling system and what is it used for?”, then you’re not alone. Here are some answers to clarify the confusion.

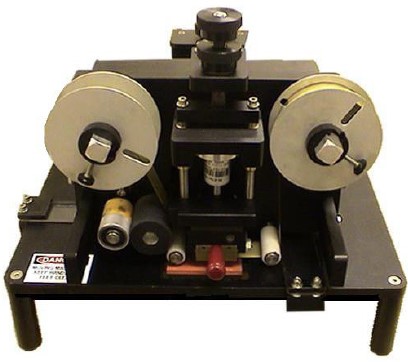

Five Reasons To Choose An Offline Coding System

If you are printing best-before or other fixed or variable information onto sleeves, pouches or cartons, an offline feed and coding system could be just what you need.

Top Trends: 3 New Types of Labeling Equipment for Your Business

As applications and requirements for labeling continue to evolve, the industry continues to push the limits of technology to respond to these new trends by delivering new types of labeling equipment that help your business respond. This blog post briefly highlights three new types of labeling equipment machines that may prove beneficial if you’re seeking to expend your product line, increase production volume, or meet new stringent labeling requirements for the industries you serve.

Debunking five myths of Thermal Inkjet (TIJ) printing

Over the past decade, designers of TIJ (Thermal inkjet) printers have worked tirelessly to address the limiting factors of the technology. The latest generation of TIJ printers will outperform CIJ (continuous inkjet) in terms of cost of ownership and print quality in most coding applications. Despite the discernible shift to TIJ, there’s still some outdated […]

Carton Labeling – Identification On All Four Sides

A specific customer request led to the development of this four side labeling system. Two corner wrap labels, one leading edge label and one trailing edge label, are printed and applied as part of a single fully integrated labeling process. The finished carton can be visually identified from any side view no matter how it […]

Case Labelers: Important Attributes to Consider

Sometimes, cases include a lot of variable data, depending on the industry or application. There can be addresses, nutritional information, bar codes, lot numbers, product identification, etc. Case labelers are a great strategy to not only save money, but they can also help to reduce the space it takes to produce custom printed cases. Instead, blank cases can be selected for different products and then labeled with variable information on an on-demand basis.

How Traceable Are Your Meal Sleeves?

Prepared foods sometimes get a bad rap, but for the busy family or professional, ready to eat meals and prepared foods can certainly be a viable and healthy option. The market has continued to grow steadily, in part because of consumer demand. Food packagers that produce these meals in high volume find that an automated […]

Creating Authentic Food Labeling

According to a study conducted by OnePoll, 75% of those who responded, noted that if the term ‘organic’ was used on the label or in the marketing campaign, they were more likely to make a purchase of said item. Nearly 60% were attracted to any given item if it was labeled ‘all natural’. The survey also found that roughly 20% of the respondents have full trust in organic food labels, with less than 60% having only partial trust.