Griffin-Rutgers labeling and coding systems are well suited for a variety of consumer goods; items such as cosmetics and personal care items, cleaning products, DVDs and CDs, tobacco, and other retail items.

The value of a product contained inside its package may be initially based on the aesthetic appeal of its packaging as a first impression marker. When it comes to any retail product, the aesthetics certainly play a part in the marketing of those products. Regardless of the appeal of products’ packaging it will likely need to have some form of coding to track it through the supply chain – at the very least a batch code.

Accuracy and speed are crucial in all aspects of printing, labeling and coding, and many consumer goods are required to comply with state and federal regulations as well as meeting specific manufacturer and industry requirements.

As you consider the purchase, we can help you determine the best product identification (labeling and coding) system for your unique needs. Contact the professionals at Griffin-Rutgers, and we will put our experience to work to select the correct system for you.

News

The Unique Uses Of Top Labeling Systems

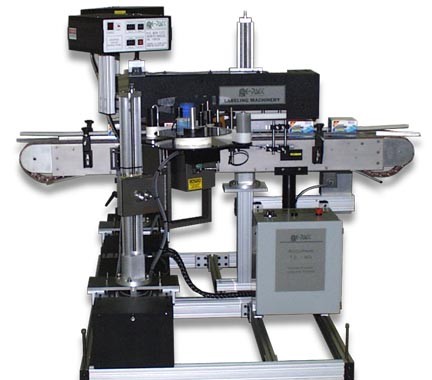

Manufacturing companies that need to print labels on their products need to first determine whether they need to print on the top or the bottom of the product or need a wrap-around system. As the professionals at Griffin-Rutgers explain there are automatic labeling systems to address each print type. Griffin-Rutgers carries a complete line of […]

On-Brand Packaging

Almost everything we eat, wear, or use comes in some sort of packaging. The package is a way to get information about your product to the consumer, but in reality, marketing places a large role in how your product is perceived. On-brand packaging creates the first impression on the potential buyer, and it’s important that […]

Basic Print & Tamp Application of A Top Panel Label

This video shows the Re-Pack Series 6 Print & Apply Labeling System in a basic top mounted print & apply installation. The label is fully printed immediately prior to being applied. The applicator vacuum tamp pads can be custom sized to fit almost any label size need. Labeler installation can be from the top, bottom, […]

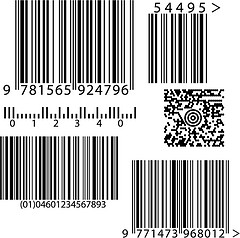

Happy Birthday To The Barcode!

Chances are you don’t pay too much attention to the barcode. It’s ubiquitous and likely a part of your everyday life. It’s a rare grocery or department store that doesn’t have bar codes on all of their products. With a simple swipe, the price and the item name are pulled up in a computer, the […]

Packaging Printing Solutions For The Cosmetic Industry

When it comes to the printing of cosmetic packaging, clarity, accuracy and appearance are crucial. Manufacturers know that the coding of cosmetic containers and packages requires a high attention to detail and they also know that printing on the high-gloss carton surfaces, plastics and glass in which cosmetics are typically packed, requires a printer that […]

Labeling Machinery for Tapered Containers from Griffin-Rutgers

This label applicator is designed to wrap labels around tapered containers. The application requires that a “Banana cut” style label is used to match the taper of the container. We have overcome the label skew issue by partially pre-dispensing the label and finishing the application at

Mini Wrap Labeler Labeling Aerosol Cans

This video is one of a series that we have posted showing the versatility of the Mini Wrap Labeling System. Be sure to view the others also. This video shows the system applying wrap labels to metal aerosol cans. The Mini Wrap is designed to fill the gap between semi-automatic labeling machines and fully automatic […]

Designing a Display Label: 4 Elements to Consider

When it comes to a display label, there are some very specific elements that you must consider when creating a design that stands out on the shelf and garners the attention you are seeking from your target customer. Here are some important elements that you will want to consider in your design.

Package Aesthetics Count When It Comes To High-End Cosmetics

The value of a product contained inside its package may be initially valued based on the aesthetic appeal of its packaging as a first impression marker. When it comes to high end, high value cosmetic products, the aesthetics certainly play a part in the marketing of those products. Regardless of the appeal of products’ packaging […]

5 Efficient Packaging Tips

If your role is as a brand manager, production or plant manager, then you know your primary focus includes the bottom line. Packaging affects many different parts of your product line, which in turn drives the growth of your business. Cost reduction and revenue growth can be tied directly to the way you package and […]

Products

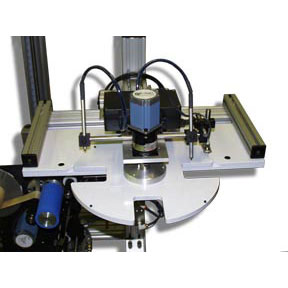

Re-Pack Dual Label Roll Unwind System with Splicing Table

Dual powered unwinds for high speed label applications providing a continuous supply of labels