Accuracy and speed are crucial in all aspects of printing and labeling and this is especially true in the pharmaceutical field. Pharmaceutical packaging and labeling are required to comply with state and federal regulations as well as meeting specific manufacturer and industry requirements.

Many pharmaceutical carton and case printing needs can be accomplished with automatic off-line feeding/printing systems. These systems save stock of preprinted products and provide only the packs that are needed and when they are needed. These technologies provide flexibility and ease of use on a myriad of package styles.

There are three types of feed systems.

- Shuttle feeders work best when the printing is required on flat cartons such as conventional reverse tuck carton or carton sleeves.

- A friction feeder is better able to handle blister cards, lidding material, seed packets and pouches, thin items such as and Tyvek® lidding material or for those cartons that need to be fed into a printer “flap first.”

- Vacuum feed systems are used for the automatic feeding of polybags, resealable pouches, asymmetric products and also crash-lock cartons.

All of these systems take the product out of a stack, print the required information and return them to a stack.

As to printing systems thermal inkjet printers (TIJ) are the usual printer of choice for pharmaceutical applications because the print is not impacted by differences in the thickness of the material being printed thereby offering greater flexibility. A thermal inkjet printer offers high resolution print, up to 600 dpi, and can also incorporate data matrix or linear barcoding technology.

That being said, the specifications that most in the pharmaceutical industry seek out in a printer are:

- The ability to add lot and expiration information and 2D Data Matrix or linear bar codes

- Inspection of printed information and code

- Automatic removal system of rejected pieces

- Serialization – the current hot topic of the industry.

Whether you’re in the market for a new off-line or in-line printing system to meet your pharmaceutical coding needs, talking with one of our professionals can help assure you get the system designed to meet your particular requirements.

You can contact us by calling 1-800-237-6713 or emailing us at custserv@griffin-rutgers.com. Our team of experts will help you find the right system for your needs and budget.

Almost everyone uses some type of pharmaceutical product so the packaging of these products is very important. Using pouches or bags with multi-layer barrier films are excellent choices for protecting your product from oxygen, moisture, and sunlight. There are different types of bags and pouches, and printing or labeling them has differing requirements. If you...Continue reading→

With the advances in technology, most industries have jumped on board to ensure that their labels, packaging, tracking system, marketing, etc., is relying on new and improved ways to keep their operations running smoothly. Using modern technology in the pharmaceutical industry is helping lower the chances of errors in medical offices, hospitals, nursing homes, etc.,...Continue reading→

Each liquid dose label is specifically designed to address individual needs in a pharmacy. From special papers and adhesives to a variety of shapes for irregular or small items, each one is designed to solve an issue for labeling oral medications.Continue reading→

One market that is advancing around the globe at a constant pace is pharmaceutical packaging. In 2018, it was estimated to reach a net worth of $78 billion, with a current rate of $20 billion a year. Packaging is key for safety, security and success.Continue reading→

Low density polyethylene (LDPE) and flexible metallized films like aluminum foil, are widely used for confectionary and salty snacks packaging. Flexible packaging is the fastest growing packaging type driven by innovations including zippers, gussets and windows. Flexible packaging is also popular because of portion control packaging and lower transportation costs.

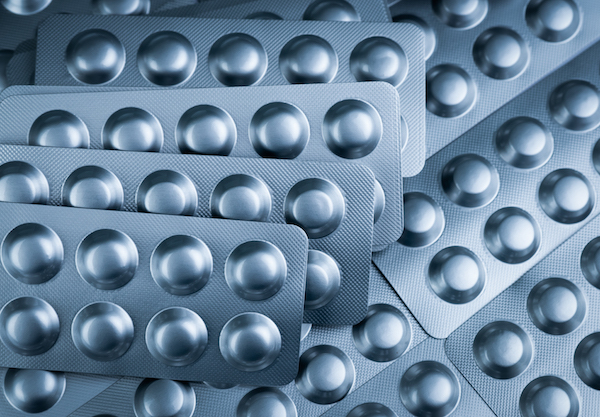

Medical aluminum foil is the material sealed onto a plastic film. The advantages of using this type of seal is that it is non-toxic, corrosion resistance, heat resistant, moisture and light resistant, and resistant to high-temperature sterilization. The typical thickness is usually 0.02 millimeter, consisting of a protective layer, printing layer, base material, and an...Continue reading→

Tyvek® is a brand of flashspun high-density polyethylene fibers, which is a synthetic material. The name is a registered trademark of the DuPont company, a company with a well-known reputation in the textile and chemical industries. Tyvek® is often used as housewrap, a synthetic material used to protect buildings during construction. The material is difficult to tear but can easily be cut with scissors or a knife. Water vapor can...Continue reading→

Packaging has changed quite a bit over the past few years. Clear packaging, like blister packs and clamshells are becoming a popular choice among manufacturers today. Some studies suggest that shoppers are as much as 400% more likely to pick up a package if they can see the product that is inside.

Growth of international free trade and inadequate drug regulations have led to the expansion of trade in counterfeit drugs worldwide. Technological protection is seen as the best way to avoid this problem. Different technologies came into existence like overt, covert, and track and trace technologies.

High resolution printing is simply not what it used to be. Advancements in technology have ensured that the printing industry can offer the best in quality, no matter the application, style or needs of the client. Of course, with better printers and higher resolutions, the need for a greater quality of ink must be at...Continue reading→