When considering the advantages of thermal transfer systems, there are some compelling reasons that make this type of package coding approach viable and strategically sound. Here are five of the more notable benefits to consider when comparing thermal transfer systems with other potential coding systems for your packaging operations:

- Durability: Thermal transfer systems use ink ribbons that can hold up to heat, chemicals, and abrasion without the risk of smudging and there is no need for drying time and limited maintenance requirements.

- Flexibility: These highly adaptable systems can code many things, including alphanumeric characters, graphics, and/or barcodes; perform with the ribbon or without by switching to direct thermal transfer (desk top models); and operate on continuously moving materials or intermittent motion materials. This versatility also applies to the amount of target material that can be covered as well as where it is installed. These systems can be used as an “over printer” within other packaging equipment, such as into a labeler or vertical form-fill-seal machine, or on its own.

- Quality/Productivity: The quality produced from such package coding systems is ideal thanks to uniform print speed . In terms of productivity, thermal transfer systems output high-quality coding at about 200 feet per minute.

- Technology: The systems are enhanced by ongoing technological innovation, which further enhances the benefits of durability, flexibility, quality and productivity while, at the same time, offering an ever user-friendly operation. For example, new coatings are being developed that can work on heat-sensitive direct thermal substrates to further the durability of the codes by making them resistant to oils, heat, and sunlight. Other innovations recently added to equipment include the use of a software-based set-up and operation to enhance usability and integration with other types of packaging systems as well as the availability of commercial ports, adjustable knobs, and quick-release parts. These innovations speed up maintenance and connectivity for greater productivity.

- Cost: The price for these units is widely varied to accommodate different needs and budgets, with pricing starting as little as $500 for a low-voltage desktop model and pushing up to $40,000 for highly sophisticated traversing systems that can be integrated within an automated packaging line to print multiple lanes while crossing the web stock.

In Review Here are the main points regarding the benefits of this type of coding approach:

- Thermal transfer systems are durable, flexible, and highly productive while still being able to produce high-quality coding capabilities.

- As a versatile machine, the systems can be integrated into a wide range of environments to handle various types of coding, materials, and types of production lines.

- Technology is regularly advanced on these machines, offering even greater usability, productivity, and flexibility for a higher value proposition than other types of coding systems.

- The cost is highly variable as there are numerous types of thermal transfer systems, depending on your need and budget.

FlexPackPro’s Thermal Transfer Overprinter, also known as TTO, is a solid printer solution for packaging machines and labelers.Continue reading→

Anytime you’re working with food products, there are a multitude of guidelines that must be followed, this is true with dairy packaging and labeling.Continue reading→

When looking for a digital, variable data coding system to invest in and depend on, it’s important to first get to know the various system manufacturers and learn how their product offerings can help you achieve your business objectives. One of the more popular coding brands today is the SmartDate family of coders. Here are five things you should know about this particular system.Continue reading→

If you are looking for a thermal transfer printer, look no further than the SmartDate Thermal Transfer Coder as it has everything you need and quite possibly more. Not surprising given the company behind the SmartDate is MARKEM, a trusted industry leader in ink and thermal printing technology.Continue reading→

Due to the changing global regulations in the medical field, the demand for innovative and effective marking and coding technologies has never been greater. Tracking medical devices through the supply chain is crucial. Not only does the packaging need to protect the device from distribution to final use, in some cases, it also maintains the...Continue reading→

When it comes to thermal transfer printing, the ribbon, substrate and printer all work together as one system. It’s simple technology and works by melting ink from the thermal transfer ribbon onto the paper or film. TTP (thermal transfer printing) is very reliable and low maintenance. TTP can be applied in a wide range of...Continue reading→

Selecting a printer for your needs can be challenging as the world of printers is vast with any number of features, gadgets, and prices. Known as a global leader in ink jet printers with a reputation of quality and reliability, UK-based Needham Printers deliver even more in terms of benefits designed to meet your business objectives. Continue reading→

At the start of the decade, QR codes began to make an appearance on almost all forms of packaging. However, if you used them for your packaging solutions back then, you probably hated them. In the beginning, the end-users had terrible experience using QR codes. They are now on the rise in many forms of...Continue reading→

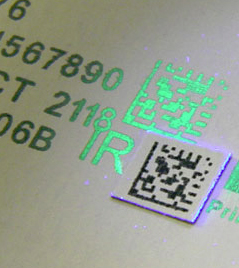

It seems impossible, but the use of printed codes on packaging continues to increase. They seem to be everywhere, on everything. Now, you can add prescription drug anti-counterfeiting measures to the list. With more requirements being set, manufacturers must ensure that they are printing codes on prescription drug packages to meet the more stringent standards.Continue reading→

When seeking a top-performing printer that can effectively deliver quality coding and printing on corrugated boxes, cases and trays, look no further than the Needham S-6000Plus. This best-of-breed ink jet machine utilizes the latest technology to provide online, high resolution capabilities that work for everything from small and large characters to bar codes and graphics. Continue reading→