A date coder plays an integral role in many types of product-based businesses, and it could be very beneficial to yours. This, of course, will depend on any specific industry requirements and particular products you are packaging. Here we break down what a date coder is and what advantageous this type of machine can provide for your business.

Date Coding Defined Coding is defined as the process of using a combination of numbers, letters, and/or images as a way to identify product information about a specific product that is then marked onto the container or packaging. Part of this product information would be a date, which could be an expiration date if it is a perishable item like food or a beverage, for example. Or, it could be a date that helps track production and delivery as part of supply chain management.

It’s Required If your business needs to work with dates, especially in relation to mandated requirements that state you must print them on a package, then you need a date coder. Requirements with the Food and Drug Administration (FDA) are increasing in terms of what type of date and other information should be included for each product type, as well as how this data should be placed so that it’s in a prominent location. This may mean changing the way you had previously included this information on product packaging. For many companies, new regulations are requiring equipment upgrades to ensure compliance. Today’s breed of date coder machines can add dates and other codes to all types of target materials, including glass, plastic, metal, film or fiber-based boxes or cases.

A Competitive Advantage Not only will this type of equipment help you meet new requirements, but it could also provide a way to gain a marketplace edge by putting your item above the rest of the market in terms of presentation/shelving, delivery, reliability and other merchandising concerns. That’s because these machines employ innovative technological advancements that provide a higher level of accuracy, also producing more consistency no matter what the batch size or run length.

Market and Strategy Changes Modern date coders are highly sophisticated machines that may do more than your business requires right now, but needs change in line with fluctuating coding requirements, volume expectations, and packaging materials and sizes. Therefore, installing a scalable machine like this now will help you address future needs without making further large capital investments.

In Review In reviewing the main reasons why you need a date coder for your business, here is a summary of the main ideas:

- It’s a requirement that you need to put dates on your products.

- It allows you to be more flexible with where you put dates or what type of packaging you can use.

- It offers a competitive advantage in terms of presentation, delivery, and reliability.

- It addresses future market and strategy changes now so you can respond quickly.

When looking for a digital, variable data coding system to invest in and depend on, it’s important to first get to know the various system manufacturers and learn how their product offerings can help you achieve your business objectives. One of the more popular coding brands today is the SmartDate family of coders. Here are five things you should know about this particular system.Continue reading→

If you are looking for a thermal transfer printer, look no further than the SmartDate Thermal Transfer Coder as it has everything you need and quite possibly more. Not surprising given the company behind the SmartDate is MARKEM, a trusted industry leader in ink and thermal printing technology.Continue reading→

Food safety is paramount for egg producers. The ability to effectively communicate traceability data and important information helps ensure producers are in compliance with safety regulations.

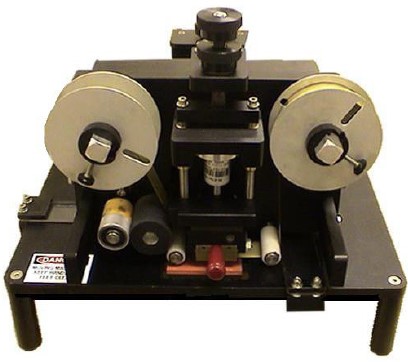

If you are printing best-before or other fixed or variable information onto sleeves, pouches or cartons, an offline feed and coding system could be just what you need.

A date coder is a printing device that adds variable information either directly onto a product, the label or to the packaging of the product. Date coding or Variable information printing can be of many different varieties ranging from a simple Production Date, Batch Number and Expiration Date to a complex 2 dimensional high density...Continue reading→

Since the inception of thermal transfer overprinters (TTOs) in the early 1990’s, Griffin-Rutgers has been there. That’s why we know that all TTOs function in the same manner, based on the identical operating principles – energize the print head, heat the ink on the mylar carrier, and with a little head pressure leave an image...Continue reading→

In recent years, pre-packaged meals have received bad press for those who are seeking a healthier lifestyle and who are turning their attention toward off-the-shelf choices. Manufacturers understand this and have been making their foods with healthier ingredients, lower sodium, fewer preservatives and in increasingly smaller packaging. The reason these meals remain popular is because...Continue reading→

As the regulatory environment continues to expand to ensure that healthcare services provide safe, secure, and confidential packaging, specialized packing and coding solutions are coming to market to address those needs.Continue reading→

When it comes to date marking, industries like food, beverage, pharmaceuticals and OEM manufacturing must ensure this critical information is printed in way that’s readable and can withstand all types of environments – even those known to be harsh on printed information. For its durability and versatility, cardboard is often the material of choice that’s utilized across a wide range of industries to package a wide range of products. Cardboard also takes well to date marking, but for added assurance it’s wise to heed some best practices related thereto.Continue reading→

When it comes to your hot stamp date coder, there are times when it might operate improperly—not unlike other types of equipment utilized for a high-demand production schedule. Better assuring the maximum performance from your date coder involves understanding the mechanics of proper work function so that you can discern when an issue is at hand. But, there are a few distinct problem signs to look out for.Continue reading→