A RFID or Radio Frequency Identification is something that transmits the identity of an object by means of radio waves. There are multiple different ways of identifying an object (human readable, bar codes, 2D codes, etc,) but the RFID premise is based around a microchip with an antenna that transmits data via a reader to a computer, which then translates the radio wave into usable information.

RFIDs have a huge benefit in terms of identifying an object over other types of identification forms such as barcodes due to the fact that they are able to transmit the information over specific ranges. This is much different than the standard barcode identification process, as it does not require direct line of site when identification occurs. The transmission range is based upon the frequency of the RFID tag but can range anywhere from one to twenty feet traditionally and can transmit even further if their own power source is supplied.

Beyond their transmitting capabilities, there are two different types of tags; one being active, the other being passive. The difference is based around the power source given to each in which active tags have their own power source which usually consists of a battery while passive tags receive their power from the computer which reads the information sent to them. There is obviously a cost difference in these two tags not to mention the distance in which they can transmit.

Finally, there is an RFID tag known as a printer encoder, which is used to print graphics or text within a smart label attached to a product. These are used to embed information into smart labels and although they are similar to most printer functions, the ability to easily transmit this information makes it a great advantage to the typical scenarios.

For more information about RFIDs and their capabilities along with other components available for product identification, visit our products page.

Most consumers are aware that there are products generally manufactured by one company but labeled with another company’s brand, aka private labeling. Not only is this beneficial to the manufacturer who profits from the sale of its product but also creates a stream of revenue from the reseller. Meanwhile, the store who is rebranding it...Continue reading→

According to a study conducted by OnePoll, 75% of those who responded, noted that if the term ‘organic’ was used on the label or in the marketing campaign, they were more likely to make a purchase of said item. Nearly 60% were attracted to any given item if it was labeled ‘all natural’. The survey also found that roughly 20% of the respondents have full trust in organic food labels, with less than 60% having only partial trust.Continue reading→

Unfortunately, brand reputations are being tarnished across the country because of the high-rate of counterfeit products. Consumers are losing trust, even amongst the most well-known brands. As a result, security labels are trending across all markets as a way to better track and prevent counterfeit products.Continue reading→

In 2018, product packaging gave manufacturers a lot of innovative ideas and options, both functionally and aesthetically. 2019 promises to be just as innovative, and continue to grow with more color, graphics and material in exciting new ways.Continue reading→

The world of labeling changes at an ever more rapid pace every day. The professionals from Griffin-Rutgers know this because manufacturers are constantly redesigning packaging components, seeking commonality of goods, and packaging lines for greater efficiency and output. Packaging systems have to keep up with such needs for ever increasing efficiency as well as new...Continue reading→

This article possibly should be titled, “Getting to the bottom of your product is a challenge.” It’s overly simplified to say the bottom of something is the bottom because it’s standing on that surface, but that’s exactly the problem – access. Bottom labeling, or coding, requires clear access to the bottom. That’s it. Systems for...Continue reading→

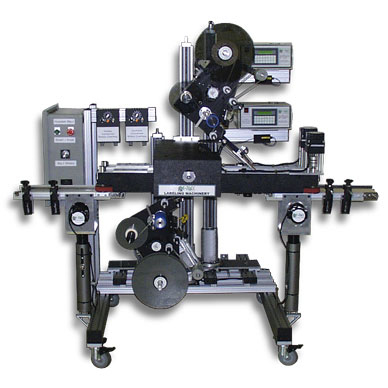

Manufacturing companies that need to print labels on their products need to first determine whether they need to print on the top or the bottom of the product or need a wrap-around system. As the professionals at Griffin-Rutgers explain there are automatic labeling systems to address each print type. Griffin-Rutgers carries a complete line of...Continue reading→

Re-Pack three roller indexing labeling systems are those designed to “orient a cylindrically shaped item and apply a wrap-around label.” In this labeling process, the label application is accurately aligned to a specific spot on the individual product item. This unique labeling process can be accomplished with a fully automated, in-line system or as an...Continue reading→

The Indexing Starwheel Labeling system manufactured by Re-Pack is one that is designed to easily integrate with an existing conveyor line system. An indexing system such as this is normally used when a label needs to be placed on the bottom of a container after the filling and capping stations. Containers such as jars, tubes,...Continue reading→

If you walk into a grocery or department store and check out the baked goods section, chances are you will look at the labels and the ingredients and some of the other packaging that those products come in. More and more consumers read labels for sugar, sodium and calories along with gluten-free, GMO information and...Continue reading→