A date coder is a printing device that adds variable information either directly onto a product, the label or to the packaging of the product. Date coding or Variable information printing can be of many different varieties ranging from a simple Production Date, Batch Number and Expiration Date to a complex 2 dimensional high density code or other type of bar code. Variable information can be required on almost any product, in some form, ranging from beer bottles, to pharmaceutical products or packaging, to a box of muffins, to flooring trim, to a yogurt cup, to a shipping carton or beverage tray. The secret is that many of these date coding applications require different types of print technology to meet the need to print on different materials and/or shapes. On this page we highlight three different date coding technologies that can address a wide range of application needs.

At Griffin-Rutgers we specialize in helping customers find the type of date coder they need to do the job at a cost point they can afford. Look below to view;

-

- A laser coder that can create a permanently etched mark that cannot be removed,

- Thermal transfer coders for coding on labels or flexible films that can print larger areas than many other coder technologies,

- Small size thermal inkjet coders that can print high resolution text, bar codes and images and at high speeds across varying surface features.

Feel free to search our site. If you have questions about the best technology for your date coding application, call Griffin-Rutgers and allow us to apply our 30 years of experience to help you find a solution to your specific need.

When looking for a digital, variable data coding system to invest in and depend on, it’s important to first get to know the various system manufacturers and learn how their product offerings can help you achieve your business objectives. One of the more popular coding brands today is the SmartDate family of coders. Here are five things you should know about this particular system.Continue reading→

If you are looking for a thermal transfer printer, look no further than the SmartDate Thermal Transfer Coder as it has everything you need and quite possibly more. Not surprising given the company behind the SmartDate is MARKEM, a trusted industry leader in ink and thermal printing technology.Continue reading→

Food safety is paramount for egg producers. The ability to effectively communicate traceability data and important information helps ensure producers are in compliance with safety regulations.

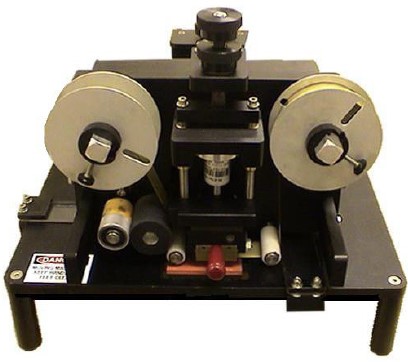

If you are printing best-before or other fixed or variable information onto sleeves, pouches or cartons, an offline feed and coding system could be just what you need.

Since the inception of thermal transfer overprinters (TTOs) in the early 1990’s, Griffin-Rutgers has been there. That’s why we know that all TTOs function in the same manner, based on the identical operating principles – energize the print head, heat the ink on the mylar carrier, and with a little head pressure leave an image...Continue reading→

In recent years, pre-packaged meals have received bad press for those who are seeking a healthier lifestyle and who are turning their attention toward off-the-shelf choices. Manufacturers understand this and have been making their foods with healthier ingredients, lower sodium, fewer preservatives and in increasingly smaller packaging. The reason these meals remain popular is because...Continue reading→

A date coder plays an integral role in many types of product-based businesses, and it could be very beneficial to yours. This, of course, will depend on any specific industry requirements and particular products you are packaging. Here we break down what a date coder is and what advantageous this type of machine can provide for your business.Continue reading→

As the regulatory environment continues to expand to ensure that healthcare services provide safe, secure, and confidential packaging, specialized packing and coding solutions are coming to market to address those needs.Continue reading→

When it comes to date marking, industries like food, beverage, pharmaceuticals and OEM manufacturing must ensure this critical information is printed in way that’s readable and can withstand all types of environments – even those known to be harsh on printed information. For its durability and versatility, cardboard is often the material of choice that’s utilized across a wide range of industries to package a wide range of products. Cardboard also takes well to date marking, but for added assurance it’s wise to heed some best practices related thereto.Continue reading→

When it comes to your hot stamp date coder, there are times when it might operate improperly—not unlike other types of equipment utilized for a high-demand production schedule. Better assuring the maximum performance from your date coder involves understanding the mechanics of proper work function so that you can discern when an issue is at hand. But, there are a few distinct problem signs to look out for.Continue reading→