The food and beverage industry covers a wide variety of items; snacks, candies, baked goods, all types of packaged meats, dairy, and many types of beverages are all included.

At Griffin Rutgers, we understand the importance of excellent print quality and ensuring operational goals are met. We offer the perfect combination of technology, expertise and service options when it comes to your choice for printing and coding on a wide range of packaging materials used within the food and beverage industry.

The Food and Drug Administration (FDA) is responsible for assuring that all foods and beverages sold in the United States are safe and properly labeled. As a result, it is imperative that labeling and coding systems can be changed seamlessly when new labeling regulations are required.

It’s important that your packaging meets the demands of the ever-changing industry and its regulations. At Griffin-Rutgers, we have a solution to meet your labeling and coding requirements. Contact us and we will put our experience to work to select the precise system to meet your needs.

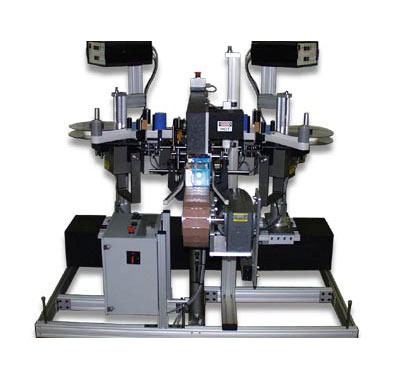

Re-Pack Series 3 Labeling Head

Direct Apply, Tamp Apply or Blow On, Stand-Alone Stepper Driven Applicators

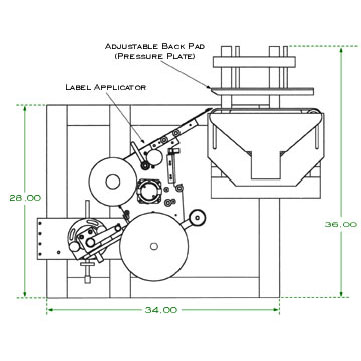

Re-Pack Wrap Labeler (Without Conveyor)

Applicator and wrap station designed to integrate with the customers existing conveyor

Dalemark Series 200 – Heavy Duty Conveyor Printer

The Series 200 HD is of such exceptionally rugged design that it is optimal for any carton, case or tray coding application or environment. It is ideal for date, batch or logo printing on almost any top, bottom or side moving surface. Its design even allows for printing on uneven or bulging surfaces. Inks are […]

Dalemark Series 100 Carton Coder

This simple coding device is designed to integrate with a conveyor transporting cartons, cases or trays. Models are available that can print either registered print in precise locations or random repeating messages. It can print on the top, side or bottom of moving packages. By using quickly interchangeable rubber type characters it produces sharp, dark, […]

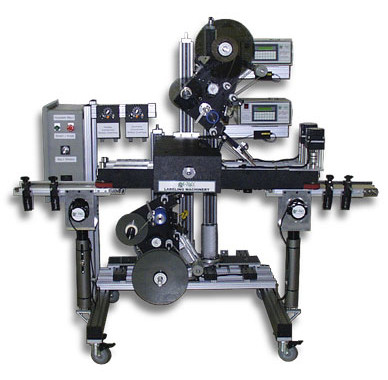

Re-Pack Mini Panel Labeling System

Entry level offering that can be equipped with the majority of the options from our Open Frame Series of labelers

Do you need to print a product identification code directly on to a bread bag? Code a lot number and expiry date on a cake or donut carton? Place a label, pre-printed or printed in-line, on a clamshell of sliced pound cake? Identify a case of whole wheat pitas with manufacturing date, expiry date, batch code and bar code or more? Put a unit and sale price on a bag lock tag? We at Griffin-Rutgers offer the solutions for all of these applications with cost-efficient, easy to operate and maintain, printing, coding and labeling systems.

Mini Panel Labeling Advantages

The Mini-Panel labeling system is one of those technologies that continues to evolve. It currently offers the flexibility of using one or two labeling heads and can be used offline (semi-automatically) or can be integrated into a production line (fully automated). Many manufacturers might consider a mini labeling system to be an “entry level” device, […]

Bottom Labeling Systems Are Different!

This article possibly should be titled, “Getting to the bottom of your product is a challenge.” It’s overly simplified to say the bottom of something is the bottom because it’s standing on that surface, but that’s exactly the problem – access. Bottom labeling, or coding, requires clear access to the bottom. That’s it. Systems for […]

Choosing the Correct Printer for Food Labeling

Food manufacturers know the importance of properly labeling food packages to meet FDA regulations. When it comes to printing on packages such as chip bags, cookie boxes or other oddly shaped or unique materials, it’s crucial to have a printer that will feed the packaging into the device and allow it to print cleanly and […]

Horizontal Packaging Needs

Improvements in technology are seen everywhere in the workforce and in consumer products and packaging. Laptop computers that used to be rather weighty now seem featherweight. Innovations in packaging also continues to grow at a steady pace. The automation of horizontal packaging allows your business to run at a more efficient rate and be able […]

Marking And Coding Solutions For Food Packaging

The US Grocery Manufacturers Association estimates that recalls cost companies over $10 million. In addition to the financial burden, recalls for defective products can also be harmful to the health of the consumer, and ultimately damage the reputation of a product and company.

Prepared, Prepackaged Meal Printing Issues

In recent years, pre-packaged meals have received bad press for those who are seeking a healthier lifestyle and who are turning their attention toward off-the-shelf choices. Manufacturers understand this and have been making their foods with more healthful ingredients, lower sodium, fewer preservatives and in increasingly smaller packaging. The reason these meals remain popular is […]

Stricter Package Labeling Being Required By The FDA

The food and medical industry seem to change and grow daily. With that, comes stricter package labeling being required by the FDA. It’s important that your packaging meets the demands of the ever-changing industry and its regulations. At Griffin-Rutgers, we have a solution to meet your labeling requirements.

‘Free From’ Labeling

It is estimated that 2 percent of adults and about 5 percent of infants and young children in the U.S. suffer from food allergies. Approximately 30,000 consumers require emergency room treatment and 150 Americans die each year because of allergic reactions to food. As a result, the FDA enacted the Food Allergen Labeling and Consumer Protection Act (FALCPA) in 2004.

Egg Coding With Thermal Inkjet Printers

Food safety is paramount for egg producers. The ability to effectively communicate traceability data and important information helps ensure producers are in compliance with safety regulations.

How to Apply Labels for Glass Bottles

Labels for glass bottles abound amid a wide range of applications, including beer and wine bottles, food jars, beverage bottles and storage bottles. These often require variable data and may need to have numerous colors and sizes with unique designs and specific printing needs. After all, many of these products rely on labels for glass bottles to make an impact on the consumer and inspire purchase with crisp, easy-to-read, and attractive graphics and text.