When it comes to date marking, industries like food, beverage, pharmaceuticals and OEM manufacturing must ensure this critical information is printed in way that’s readable and can withstand all types of environments – even those known to be harsh on printed information. For its durability and versatility, cardboard is often the material of choice that’s utilized across a wide range of industries to package a wide range of products. Cardboard also takes well to date marking, but for added assurance it’s wise to heed some best practices related thereto.

Date Marking with CO2 Laser Technology: A best practice for this type of printing onto cardboard is to consider using CO2 laser technology. These laser coders use electrical energy to prompt the laser’s carbon dioxide gas to emit a beam of invisible light. This heats the surface so that the information can be engraved on the surface of the packaging or that a pre-printed colored block is etched , which then creates the mark. The beam of light that comes from the laser is directed at movable mirrors controlled by a computer, which then creates a dot matrix image of the mark that is to be applied to the cardboard box or other type of packaging. A prime example of machine that employs this best practice is the MARKEM SmartLase, which optimizes the area to be marked on the packaging so that an air-cooled laser can be used to do the marking. Its small size, yet powerful laser technology, keeps the process low cost. The machine is also versatile as it can print on both stationary and moving surfaces.

Green Machine: Another best practice related to printing with a CO2 laser date marking machine is in the realm of environmental sustainability given the low amount of energy that is used, which also delivers a lower utility cost. Beyond its eco-friendly benefits, this type of technology also allows for a greater level of control over the process to ensure that high standard of quality while still providing for the necessary flexibility to print a wide range of dates and information onto cardboard packages. Ensuring versatility and adaptability is another certain best practice. In kind, it’s also notable that the MARKEM date marker with CO laser technology fits anywhere along the production line—no matter the production line configuration—as the printer is small and can be easily modified. Taken altogether, these are best practices that can lead to date marking excellence on cardboard boxes not to mention many other types of materials.

The main points to remember include the following:

- Accurate and durable date marking is critical to a wide range of industries, including food, beverage, pharmaceuticals and OEM manufacturing.

- Date marking best practices includes the use of CO2 laser technology for precise and durable marking of information on cardboard boxes and other substrates.

- Cost savings, flexibility, adaptability and low energy use are other best practices commonly found in MARKEM’s SmartLase machine.

When looking for a digital, variable data coding system to invest in and depend on, it’s important to first get to know the various system manufacturers and learn how their product offerings can help you achieve your business objectives. One of the more popular coding brands today is the SmartDate family of coders. Here are five things you should know about this particular system.Continue reading→

If you are looking for a thermal transfer printer, look no further than the SmartDate Thermal Transfer Coder as it has everything you need and quite possibly more. Not surprising given the company behind the SmartDate is MARKEM, a trusted industry leader in ink and thermal printing technology.Continue reading→

Paperboard and folding cartons for retail and product manufacturing is becoming a desired choice for product packaging solutions. The multitude of benefits that paperboard offers across its lifecycle – from manufacturing to retailing to consumption and recycling – is becoming clearer every day.

Food safety is paramount for egg producers. The ability to effectively communicate traceability data and important information helps ensure producers are in compliance with safety regulations.

Needham Coding is a leading global manufacturer and supplier of state-of-the-art high resolution ink jet printers for the packaging industry. For almost 60-years, Needham Coding has been on the cutting edge of package identification, now using its own research and development department to advance ink jet technologies. Indeed, the company’s line of printers are revered...Continue reading→

When seeking a top-performing printer that can effectively deliver quality coding and printing on corrugated boxes, cases and trays, look no further than the Needham S-6000Plus. This best-of-breed ink jet machine utilizes the latest technology to provide online, high resolution capabilities that work for everything from small and large characters to bar codes and graphics. Continue reading→

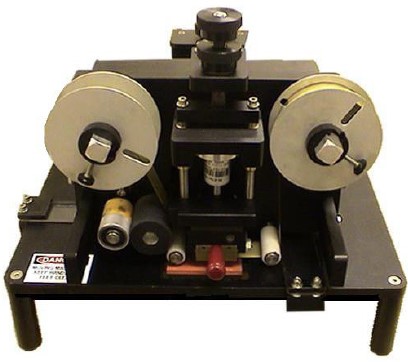

If you are printing best-before or other fixed or variable information onto sleeves, pouches or cartons, an offline feed and coding system could be just what you need.

A date coder is a printing device that adds variable information either directly onto a product, the label or to the packaging of the product. Date coding or Variable information printing can be of many different varieties ranging from a simple Production Date, Batch Number and Expiration Date to a complex 2 dimensional high density...Continue reading→

Since the inception of thermal transfer overprinters (TTOs) in the early 1990’s, Griffin-Rutgers has been there. That’s why we know that all TTOs function in the same manner, based on the identical operating principles – energize the print head, heat the ink on the mylar carrier, and with a little head pressure leave an image...Continue reading→

In recent years, pre-packaged meals have received bad press for those who are seeking a healthier lifestyle and who are turning their attention toward off-the-shelf choices. Manufacturers understand this and have been making their foods with healthier ingredients, lower sodium, fewer preservatives and in increasingly smaller packaging. The reason these meals remain popular is because...Continue reading→