If you are a manufacturer that works with folding cartons, you have no doubt been faced with the issue that this type of container poses for your coding and marking procedures. You understand that the variable data that needs to be applied to a carton is only one element of the entire production and printing process.

Even though this may seem to be a process that isn’t that high of a priority, its importance will be evident when someone in the organization needs to apply a label. In fact, with folding cartons, you may find it nearly impossible unless you have the correct printer and/or labels for the job! In some cases the printer you’re using may be able to perform the task, but if you’re printing on containers, such as cracker boxes, soup containers, prescription bottles and other consumer goods, you may find printing on folding cartons is not a task your current print set up can handle.

The reason for the increase in the need to print on folding containers is that businesses are looking toward more environmentally friendly practices and packaging is one of the areas in which they believe they can make an impact. Many folding cartons are made from recyclable and biodegradable materials. In addition these cartons are also lightweight and can be packed and shipped in flat form. These containers, even when filled, are easy to pack and transport.

Folding cartons also offer aesthetic appeal to the consumer. Manufacturers appreciate the cartons because they allow for a full front view when their products are on the grocery store shelf. The front can feature the brand’s design while the ingredient list, use by date, and other pertinent information is printed on the non-front-facing area.

When talking with the professionals at Griffin-Rutgers you may want to ask about an offline printing process. With this type of print set up, the cartons will be printed on before they reach the production line. An offline printing system is beneficial because of the very nature of the carton’s shape allowing the packaging manager to rest easy knowing that all of the pertinent information will be printed on the carton when it is delivered to them for filling and shipping.

Whether you’re a first year start-up, a larger company that has only a small need for high resolution printing or a company that has a large need for high resolution printing there’s a good chance you’re looking for a low-cost way to code your packages. But, of course, you still want to look professional in...Continue reading→

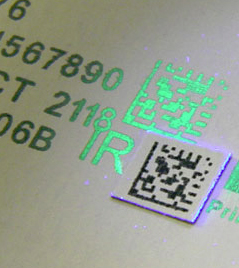

Growth of international free trade and inadequate drug regulations have led to the expansion of trade in counterfeit drugs worldwide. Technological protection is seen as the best way to avoid this problem. Different technologies came into existence like overt, covert, and track and trace technologies.

High resolution printing is simply not what it used to be. Advancements in technology have ensured that the printing industry can offer the best in quality, no matter the application, style or needs of the client. Of course, with better printers and higher resolutions, the need for a greater quality of ink must be at...Continue reading→

The Needham S-6000 series is a great alternative to CIJ (Continuous Ink Jet) due to its ease of use and simplified maintenance benefits.Continue reading→

At the start of the decade, QR codes began to make an appearance on almost all forms of packaging. However, if you used them for your packaging solutions back then, you probably hated them. In the beginning, the end-users had terrible experience using QR codes. They are now on the rise in many forms of...Continue reading→

It seems impossible, but the use of printed codes on packaging continues to increase. They seem to be everywhere, on everything. Now, you can add prescription drug anti-counterfeiting measures to the list. With more requirements being set, manufacturers must ensure that they are printing codes on prescription drug packages to meet the more stringent standards.Continue reading→

When seeking a top-performing printer that can effectively deliver quality coding and printing on corrugated boxes, cases and trays, look no further than the Needham S-6000Plus. This best-of-breed ink jet machine utilizes the latest technology to provide online, high resolution capabilities that work for everything from small and large characters to bar codes and graphics. Continue reading→

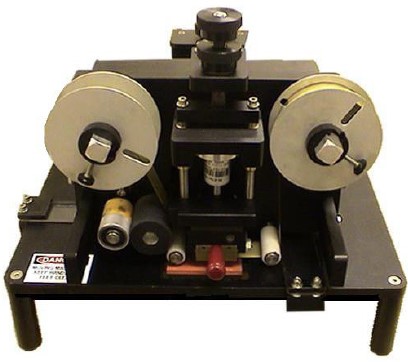

If you are printing best-before or other fixed or variable information onto sleeves, pouches or cartons, an offline feed and coding system could be just what you need.

Accuracy and speed are crucial in all aspects of printing and labeling and this is especially true in the pharmaceutical field. Pharmaceutical packaging and labeling are required to comply with state and federal regulations as well as meeting specific manufacturer and industry requirements. Many pharmaceutical carton and case printing needs can be accomplished with automatic...Continue reading→

Carton Coding machines have numerous usages but pharmaceutical carton printing has created an industry based on the benefits of offline carton coding. Because pharmaceutical cartons are many times constructed a specific way, they create a high demand for offline machines. Often, pharmaceutical cartons are used for the packing of multiple packs, labeled erect and put...Continue reading→