An in-house, stand-alone, fully automated carton printing system can provide a myriad of benefits to bottom-line minded businesses. From on-demand printing to ensure up-to-date information accuracy and design flexibility, to the elimination of outdated pre-printed material inventory and the avoidance of overstocks and shortages, a carton printing system can deliver a fast ROI in droves. However, it is important to make a careful and thoughtful investment when considering such a solution as all are not created equal. Indeed, there are a number of guidelines to keep top-of-mind as you vet systems for purchase.

An in-house, stand-alone, fully automated carton printing system can provide a myriad of benefits to bottom-line minded businesses. From on-demand printing to ensure up-to-date information accuracy and design flexibility, to the elimination of outdated pre-printed material inventory and the avoidance of overstocks and shortages, a carton printing system can deliver a fast ROI in droves. However, it is important to make a careful and thoughtful investment when considering such a solution as all are not created equal. Indeed, there are a number of guidelines to keep top-of-mind as you vet systems for purchase.

Carton Printing Criteria

- Material – first review the carton and its design. Is it necessary to print the entire side of the carton, multiple areas or one specific spot? Is the area(s) to be printed all the same thickness when the carton is lying flat? Does it have the same number of layers of material uniformly under the print location. If there is an overprint varnish, is it laid out entirely over the substrate? Will the carton transport easily either individually or from a feed magazine? What is the overall size of the print image (width by length) versus the overall carton size (width by length). The answers to these questions will help direct you to the right printing technology for your application.

- Quality: Considered one of the most crucial elements, a professional aesthetic, quality, and readability are a must for cartons as misprints and illegible print can have serious implications. Factors here can include type clarity of the text, images and barcodes, color quality, and special coating and security features. A machine with higher resolution capability helps to address some of these issues. For example, advanced technology multi-head ink jet printing systems ensure excellent print images.

- Ease of Use: The printing system must be easy for many different people to handle and operate also minimizing the time required for training at the onset. Having a fully-automated, user-friendly system can not only enhance the accuracy, efficiency, and productivity related to carton production, but it can also reduce human error.

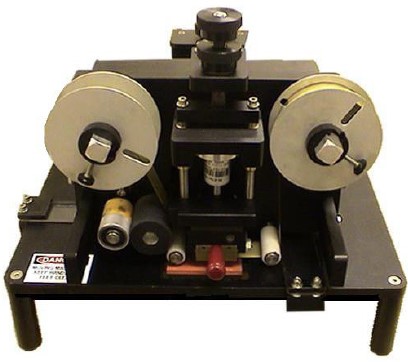

- Functionality: While the best carton printing systems can print on various substrates, they should also have other robust features. This might include UV inks with LED- UV Curing technology for printing cartons completely or other variable information, text and data, built-in number generation for serializing or coding, and highly customizable imager configurations. Look for machines that offer flexibility to be able to add further print capacity on an as-needed basis.

- Performance: Particularly when volume is a concern, it is important to procure a “workhorse” that has a proven reputation as a high-performance machine that can go the distance. Such durability and longevity will negate a need for costly system repairs and downtime.

- Service: No machine is completely infallible. Production and quality standards can be adversely impacted when equipment malfunctions or other issues arise. That’s why it is good to select a system from a supplier that offers comprehensive service and support, including delivery, installation and setup, training, ongoing technical assistance, and as-needed equipment repair.

In Summary when looking for a printing system that delivers the goods for quality carton printing, remember to focus on the following:

- Quality is King. Ascertain features that specifically assure a high level of print accuracy and integrity with respect to text, images, colors and all other production elements.

- Make sure the system is easy to use and that proper training on the equipment will be provided by the seller.

- Pick the machine with the most diverse and scalable feature set to suit printing needs today and in the future.

- Get input on the performance history of each machine considered for purchase to make sure it is built to last. Pursue customer references in this regard.