In recent years, pre-packaged meals have received bad press for those who are seeking a healthier lifestyle and who are turning their attention toward off-the-shelf choices. Manufacturers understand this and have been making their foods with healthier ingredients, lower sodium, fewer preservatives and in increasingly smaller packaging.

The reason these meals remain popular is because of the hectic lifestyle that families and working individuals are faced with. Whether they’re buying their pre-packaged meals from the freezer or refrigerator section, the packaging remains a high priority to the manufacturer.

Griffin-Rutgers shares that these pre-packaged meals need to have “use by dates” bar codes and traceability codes. The printing of these codes need to be done on both the plastic container and in some cases the cardboard wrap-around sleeves. This can pose a unique set of challenges on the manufacturing and production floor.

Automated sleeving machines are ideal until it comes to the time to apply the traceability or use-by date codes. In order to have the codes print correctly it’s crucial that the sleeves do not shift during its movement down the assembly and packing line. Griffin-Rutgers printing professionals recognize that there are multiple solutions. One solution is to code the sleeves offline, bring them to the line printed then automate the actual “sleeving” of the plastic container.

An offline coding system works best for this process and also offers other benefits, including:

- Reduced downtime to change from one product to another

- Enhanced flexibility to print on off-sized packaging and the ability to stack items for printing on more than one area

- Throughput increases because of a move away from manual systems.

- Offline coding enhances positional accuracy and could potentially increase line speeds.

A second solution is the printing of the required information in-line. This can be done by thermal ink jets (TIJ”s), continuous ink jets (CIJ’s), lasers and, at times, thermal transfer systems. If you’re faced with printing “use by” codes, track and trace or other information on your products, Griffin Rutgers can help you identify the best system for your business.

When looking for a digital, variable data coding system to invest in and depend on, it’s important to first get to know the various system manufacturers and learn how their product offerings can help you achieve your business objectives. One of the more popular coding brands today is the SmartDate family of coders. Here are five things you should know about this particular system.Continue reading→

If you are looking for a thermal transfer printer, look no further than the SmartDate Thermal Transfer Coder as it has everything you need and quite possibly more. Not surprising given the company behind the SmartDate is MARKEM, a trusted industry leader in ink and thermal printing technology.Continue reading→

Food safety is paramount for egg producers. The ability to effectively communicate traceability data and important information helps ensure producers are in compliance with safety regulations.

Compared to the traditional printing processes used in the printing of packaging such as flexography and offset lithography, inkjet as a primary method of package printing is relatively new. It’s also an area of growth and opportunity that did not go unnoticed at Drupa 2016, as many vendors focused on packaging solutions using digital inkjet...Continue reading→

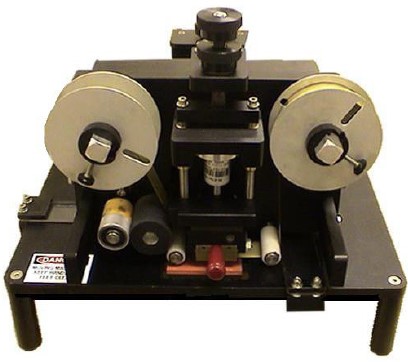

If you are printing best-before or other fixed or variable information onto sleeves, pouches or cartons, an offline feed and coding system could be just what you need.

In every industry, the trend for more eco-friendly packaging is taking an upturn. We are seeing that trend even in the cosmetic industry. When one thinks ‘cosmetics’ it brings to mind makeup, but, the cosmetic industry encompasses more than just eye shadow and blush. It includes everything from toothpaste to lipsticks. As such, it needs...Continue reading→

A date coder is a printing device that adds variable information either directly onto a product, the label or to the packaging of the product. Date coding or Variable information printing can be of many different varieties ranging from a simple Production Date, Batch Number and Expiration Date to a complex 2 dimensional high density...Continue reading→

Since the inception of thermal transfer overprinters (TTOs) in the early 1990’s, Griffin-Rutgers has been there. That’s why we know that all TTOs function in the same manner, based on the identical operating principles – energize the print head, heat the ink on the mylar carrier, and with a little head pressure leave an image...Continue reading→

Manufacturers and packagers of pharmaceutical products understand that a product identification system for pharmaceutical packaging requires two separate, but highly integrated components. It is mandatory to have a labeling system that can consistently apply labels at the required speed and with a high degree of accuracy. Along with such a labeler packagers need a print...Continue reading→

Accufast P-4 printing on Seed PacketsThe Accufast P4 is a complete, desk top sized, system for feeding transporting and printing on cartons, cards, sleeves and envelopes. It can print an area up to 2” x 12” or that area can be divided into two independently located 1” x 12” areas. The system can transport materials...Continue reading→