Before selecting coding equipment for your business, it is important to understand the full capabilities of what your model of choice can do, what type of printing technologies it employs, what materials it can accommodate and other critical factors that are integral to the purchase decision. Of primary importance is understanding the fundamental purpose of coding equipment. Here is a rundown on what this type of machine can do, and the type of target materials it performs with best. Coding Equipment Clarified The primary purpose of such machines is to print characters onto various types of packaging (primary, secondary, and tertiary), labels, and distribution packaging. The characters, or codes, can include:

Before selecting coding equipment for your business, it is important to understand the full capabilities of what your model of choice can do, what type of printing technologies it employs, what materials it can accommodate and other critical factors that are integral to the purchase decision. Of primary importance is understanding the fundamental purpose of coding equipment. Here is a rundown on what this type of machine can do, and the type of target materials it performs with best. Coding Equipment Clarified The primary purpose of such machines is to print characters onto various types of packaging (primary, secondary, and tertiary), labels, and distribution packaging. The characters, or codes, can include:

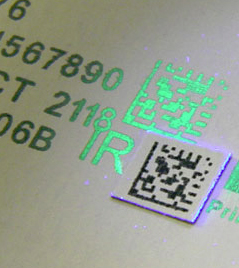

- letters and numbers,

- images and graphics,

- logos,

- barcodes,

- dates,

- two-dimensional and lot codes, and

- other types of information.

Target materials that work well with coding equipment include:

- plastic,

- glass,

- metal,

- fiber-based cases and boxes,

- film, foil, paper and other flexible materials, and

- labels.

In order to work with these targets and coding information, the equipment uses many types of printing technologies such as:

- thermal transfer,

- laser,

- ink jet,

- embossing,

- hot-stamping,

- wet ink, and

- stencil.

To get the best results for your particular products and productivity objectives, it is important to know that certain coding equipment with specific printing technologies may be more effective than others. Some things to think about include:

- the type of substrate you are using to make sure that the ink bonds well;

- whether you will be doing continuous or intermittent motion production;

- batch size and run length of each printing session;

- whether you have static or variable information;

- size of coding content and whether you need to include barcodes; and

- the environment where the packaging will be placed to ensure coded information integrity.

Other operational factors to consider include:

- how much expense the coder will produce in regards to the operation, such as inks and consumable, labor and training costs, maintenance and repair costs, etc,;

- whether there will be any environmental concerns to consider; and

- the working position of the coder in terms of distance between the printer and the target substrate and whether it will need to be mounted on the conveyor to maximize its use but decrease its vulnerability to contaminating elements.

In Summary In summarizing this blog post, here are the main points:

- Coding equipment prints various types of characters onto a range of target materials.

- Coding equipment can use a wide array of printing technologies.

When looking for a digital, variable data coding system to invest in and depend on, it’s important to first get to know the various system manufacturers and learn how their product offerings can help you achieve your business objectives. One of the more popular coding brands today is the SmartDate family of coders. Here are five things you should know about this particular system.Continue reading→

If you are looking for a thermal transfer printer, look no further than the SmartDate Thermal Transfer Coder as it has everything you need and quite possibly more. Not surprising given the company behind the SmartDate is MARKEM, a trusted industry leader in ink and thermal printing technology.Continue reading→

Food safety is paramount for egg producers. The ability to effectively communicate traceability data and important information helps ensure producers are in compliance with safety regulations.

Selecting a printer for your needs can be challenging as the world of printers is vast with any number of features, gadgets, and prices. Known as a global leader in ink jet printers with a reputation of quality and reliability, UK-based Needham Printers deliver even more in terms of benefits designed to meet your business objectives. Continue reading→

At the start of the decade, QR codes began to make an appearance on almost all forms of packaging. However, if you used them for your packaging solutions back then, you probably hated them. In the beginning, the end-users had terrible experience using QR codes. They are now on the rise in many forms of...Continue reading→

It seems impossible, but the use of printed codes on packaging continues to increase. They seem to be everywhere, on everything. Now, you can add prescription drug anti-counterfeiting measures to the list. With more requirements being set, manufacturers must ensure that they are printing codes on prescription drug packages to meet the more stringent standards.Continue reading→

When seeking a top-performing printer that can effectively deliver quality coding and printing on corrugated boxes, cases and trays, look no further than the Needham S-6000Plus. This best-of-breed ink jet machine utilizes the latest technology to provide online, high resolution capabilities that work for everything from small and large characters to bar codes and graphics. Continue reading→

The plant and garden industries strive to provide valuable information for their customers to help maintain the beauty and life of all types of greenery. And, for green thumbs to benefit from the information, they need to be able to see it. This means that printing on plant trays plays an integral role because the...Continue reading→

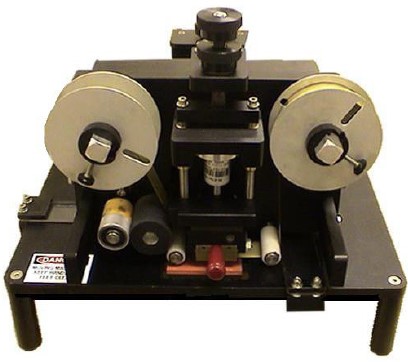

If you are printing best-before or other fixed or variable information onto sleeves, pouches or cartons, an offline feed and coding system could be just what you need.

A date coder is a printing device that adds variable information either directly onto a product, the label or to the packaging of the product. Date coding or Variable information printing can be of many different varieties ranging from a simple Production Date, Batch Number and Expiration Date to a complex 2 dimensional high density...Continue reading→

Before selecting coding equipment for your business, it is important to understand the full capabilities of what your model of choice can do, what type of printing technologies it employs, what materials it can accommodate and other critical factors that are integral to the purchase decision. Of primary importance is understanding the fundamental purpose of coding equipment. Here is a rundown on what this type of machine can do, and the type of target materials it performs with best. Coding Equipment Clarified The primary purpose of such machines is to print characters onto various types of packaging (primary, secondary, and tertiary), labels, and distribution packaging. The characters, or codes, can include:

Before selecting coding equipment for your business, it is important to understand the full capabilities of what your model of choice can do, what type of printing technologies it employs, what materials it can accommodate and other critical factors that are integral to the purchase decision. Of primary importance is understanding the fundamental purpose of coding equipment. Here is a rundown on what this type of machine can do, and the type of target materials it performs with best. Coding Equipment Clarified The primary purpose of such machines is to print characters onto various types of packaging (primary, secondary, and tertiary), labels, and distribution packaging. The characters, or codes, can include: