With such a great need for accuracy and performance when shipping products, selecting the right carton printing system is a must rather than just making a purchase based on price or popularity of a certain model. This article breaks down some of the most important factors to consider before committing to buying.

Guidelines for Purchase

The following should be considered when thinking about investing in a carton printing system that can deliver on-demand printing with the greatest level of accuracy and flexibility in its design capabilities.

The top factors are:

- Project Criteria: Fully evaluate and document the performance criteria of your project requirements. This should include information such as the material to be printed, required print speed, print image content, whether static or dynamic information is to be printed and how the carton will be moved. It is also important to understand the requirements of your specific industry when choosing a carton printing system.

- Performance: If high volume is a part of your business, then it is particularly important to purchase a machine that is a proven workhorse. Although no machine is perfect in its performance, malfunctions will occur. Just make sure that all performance history has been researched on each machine to ensure low-cost, minimal repairs as well as responsive service and support.

- Functionality: Consider this the “Litmus Test” to see just how much the carton printing system can do for you. This might involve considering the print capability for time and date, carton counts, barcodes on various materials as well as the function of remote network control. Be sure to consider its capacity for additional print capacity as your business grows.

- Ease of Use: The ability to use the carton printing system with minimal training is critical because the user-friendly capability can ensure accurate and productive printing while reducing training expense.

- Quality: As the central focus of all printing jobs, quality must be a priority factor to consider. Ensure that the system can deliver readability, correct printing specs, sharp / clear images and barcodes and other required data. The quality of the printed image reflects directly on your company and sends a message to the carton recipient.

In Review

The highlights to focus on when making your decision on the right carton printing system include the following factors:

- Determine your project criteria and performance needs. While many factors can influence the decision to find the right carton printer, industry needs and demands must be considered.

- Overall print quality is the most important factor followed by performance, functionality, reliability and ease of use.

- Not every factor is uniform across businesses that want to print on cartons. There are individual and unique needs that a company must consider in their purchase decisions when choosing a carton printing system.

Growth of international free trade and inadequate drug regulations have led to the expansion of trade in counterfeit drugs worldwide. Technological protection is seen as the best way to avoid this problem. Different technologies came into existence like overt, covert, and track and trace technologies.

High resolution printing is simply not what it used to be. Advancements in technology have ensured that the printing industry can offer the best in quality, no matter the application, style or needs of the client. Of course, with better printers and higher resolutions, the need for a greater quality of ink must be at...Continue reading→

Needham Coding is a leading global manufacturer and supplier of state-of-the-art high resolution ink jet printers for the packaging industry. For almost 60-years, Needham Coding has been on the cutting edge of package identification, now using its own research and development department to advance ink jet technologies. Indeed, the company’s line of printers are revered...Continue reading→

The Needham S-6000 series is a great alternative to CIJ (Continuous Ink Jet) due to its ease of use and simplified maintenance benefits.Continue reading→

When seeking a top-performing printer that can effectively deliver quality coding and printing on corrugated boxes, cases and trays, look no further than the Needham S-6000Plus. This best-of-breed ink jet machine utilizes the latest technology to provide online, high resolution capabilities that work for everything from small and large characters to bar codes and graphics. Continue reading→

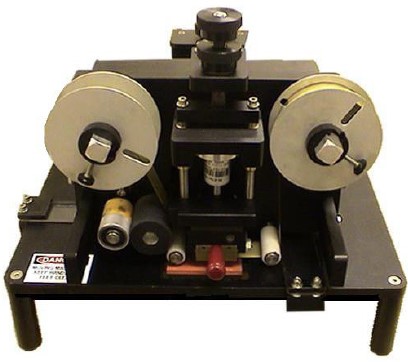

If you are printing best-before or other fixed or variable information onto sleeves, pouches or cartons, an offline feed and coding system could be just what you need.

Accuracy and speed are crucial in all aspects of printing and labeling and this is especially true in the pharmaceutical field. Pharmaceutical packaging and labeling are required to comply with state and federal regulations as well as meeting specific manufacturer and industry requirements. Many pharmaceutical carton and case printing needs can be accomplished with automatic...Continue reading→

If you are a manufacturer that works with folding cartons, you have no doubt been faced with the issue that this type of container poses for your coding and marking procedures. You understand that the variable data that needs to be applied to a carton is only one element of the entire production and printing...Continue reading→

Carton Coding machines have numerous usages but pharmaceutical carton printing has created an industry based on the benefits of offline carton coding. Because pharmaceutical cartons are many times constructed a specific way, they create a high demand for offline machines. Often, pharmaceutical cartons are used for the packing of multiple packs, labeled erect and put...Continue reading→

When the holidays roll around, how can you set your product apart from the others that crowd the shelves and vie for your customer’s attention? One way is through the use of festive sleeves for your products. Food products effectively lend themselves to festive sleeves or cartons and with eye catching packaging you may see...Continue reading→