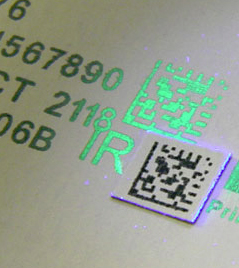

At the start of the decade, QR codes began to make an appearance on almost all forms of packaging. However, if you used them for your packaging solutions back then, you probably hated them. In the beginning, the end-users had terrible experience using QR codes. They are now on the rise in many forms of commerce. Griffin-Rutgers has options for QR codes and your packaging solutions.

There are a few reasons QR codes have failed as a marketing tool in the past. At the time, most people were not connected via their smartphones. If they did have them, they needed to download an app to scan the applicable QR code. Once the app was downloaded, the customer would need to take a picture; process it; and then they would be re-directed to the product’s web site. Since mobile internet connections were very sl ow, the websites took a long time to load and once they did, the web pages weren’t optimized for mobile landing pages, making the entire effort put into it by the customer, simply not worth it.

ow, the websites took a long time to load and once they did, the web pages weren’t optimized for mobile landing pages, making the entire effort put into it by the customer, simply not worth it.

However, that was back in 2010. In 2018, the amount of people using QR codes is in the millions. They are making a huge comeback. This indicates that QR codes were ahead of their time. Now, they make a lot of sense.

Many things have changed since then. Technology and consumer behavior are directly responsible for the rise of QR codes in today’s commerce market.

Printing a QR code onto your packaging can help engage your potential customers and further drive sales of your end-products. Things like:

- Show what the product will actually do.

- Make product registration easy.

- Link to consumer reviews of your product and how it stands out from the others.

- Give buyers an instant coupon if they purchase your product.

- Provide different tips about how to use your product.

The various printer technologies we offer at Griffin-Rutgers can be set up to print the entire label copy, including the QR Code to more efficiently market your products.

Millennials are eager to engage with QR code technology, as they enjoy the interaction with conventional and emerging technologies. There is no doubt that the concept behind QR codes is brilliant, and as consumers demand a more interactive experience, future packaging endeavors will need to be more innovative, going beyond visual appeal to packaging immersed with multi-media information.

We at Griffin-Rutgers can help you configure the optimal solution for your production line printing and labeling needs to incorporate QR coding.

Whether you’re a first year start-up, a larger company that has only a small need for high resolution printing or a company that has a large need for high resolution printing there’s a good chance you’re looking for a low-cost way to code your packages. But, of course, you still want to look professional in...Continue reading→

Selecting a printer for your needs can be challenging as the world of printers is vast with any number of features, gadgets, and prices. Known as a global leader in ink jet printers with a reputation of quality and reliability, UK-based Needham Printers deliver even more in terms of benefits designed to meet your business objectives. Continue reading→

It seems impossible, but the use of printed codes on packaging continues to increase. They seem to be everywhere, on everything. Now, you can add prescription drug anti-counterfeiting measures to the list. With more requirements being set, manufacturers must ensure that they are printing codes on prescription drug packages to meet the more stringent standards.Continue reading→

When seeking a top-performing printer that can effectively deliver quality coding and printing on corrugated boxes, cases and trays, look no further than the Needham S-6000Plus. This best-of-breed ink jet machine utilizes the latest technology to provide online, high resolution capabilities that work for everything from small and large characters to bar codes and graphics. Continue reading→

The plant and garden industries strive to provide valuable information for their customers to help maintain the beauty and life of all types of greenery. And, for green thumbs to benefit from the information, they need to be able to see it. This means that printing on plant trays plays an integral role because the...Continue reading→

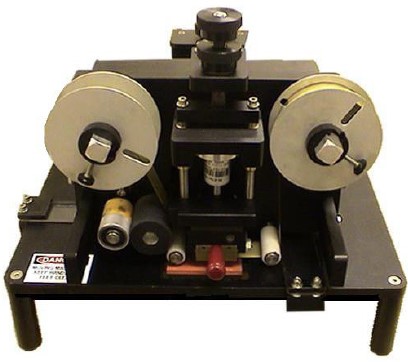

If you are printing best-before or other fixed or variable information onto sleeves, pouches or cartons, an offline feed and coding system could be just what you need.

If you are a manufacturer that works with folding cartons, you have no doubt been faced with the issue that this type of container poses for your coding and marking procedures. You understand that the variable data that needs to be applied to a carton is only one element of the entire production and printing...Continue reading→

Carton Coding machines have numerous usages but pharmaceutical carton printing has created an industry based on the benefits of offline carton coding. Because pharmaceutical cartons are many times constructed a specific way, they create a high demand for offline machines. Often, pharmaceutical cartons are used for the packing of multiple packs, labeled erect and put...Continue reading→

High quality, high speed and flexible coding options are three of the reasons that thermal inkjet printers (TIJ) are typically chosen for use in the packaging industry. This technology provides a clean print, is reliable and is virtually maintenance free. Thermal inkjet printers can be used in industrial applications that require printing on both porous...Continue reading→

The Markoprint X1Jet HP is one of the most compact coding systems available on the market. It is designed to label and format data created by PC-based software and then sent via Ethernet or USB stick to the substrate upon which the data is printed. It fulfills standard marking and coding requirements such as text,...Continue reading→

ow, the websites took a long time to load and once they did, the web pages weren’t optimized for mobile landing pages, making the entire effort put into it by the customer, simply not worth it.

ow, the websites took a long time to load and once they did, the web pages weren’t optimized for mobile landing pages, making the entire effort put into it by the customer, simply not worth it.