Unfortunately, brand reputations are being tarnished across the country because of the high-rate of counterfeit products. Consumers are losing trust, even amongst the most well-known brands. As a result, security labels are trending across all markets as a way to better track and prevent counterfeit products.

Particularly within the food and beverage industry, printed security labels with irreversible thermochromic ink technology can let the consumer know it is safe to consume. The ink changes colors in response to temperature fluctuations. Distributors use this label technology to see if a product is tainted and can pull the product before selling.

We are all becoming more aware of the necessity for security in just about everything that we do, the same applies in the world of business. It has been known for assets to “disappear” or it could be that they have simply been misplaced. This can be a primary reason why companies are increasingly turning to security labels.

Serial I.D.s, tamper evident labels, mini QR codes, void film and RFID tags are also gaining popularity to help fight the war on counterfeiting, product diversion and product tampering.

There are many different types of security labels. For instance:

- Security label with a QR code

- Two-tone labels

- Two-tone Dot Matrix security labels

- Tear & Sew labels

- Silicon Encapsulated Hologram labels

They can also come in one of two distinct forms: a void label which is adhered to the surface of an item, and should anyone attempt to remove the label, the word ‘void’ appears and remains on the item. The second is the destructible label, which, as the name implies, should this type be tampered with, the label will split apart in sections. This will cause anyone to know immediately that the product has been tampered with.

The material choice will depend upon the general location of the item, possible method of transportation as well as storage. The most commonly used material is plastic, but increasingly we are seeing the use of metal as well as fiber.

You can also:

- Add barcodes and numbering to your labels. Ensuring an easy way to track your product and/or equipment

- Customize your labels with your own graphics, i.e., text, color, and logo design

- Use Die-cut labels that feature unique shapes that are difficult to reproduce, such as octagons, butterfly, or rounded rectangular labels

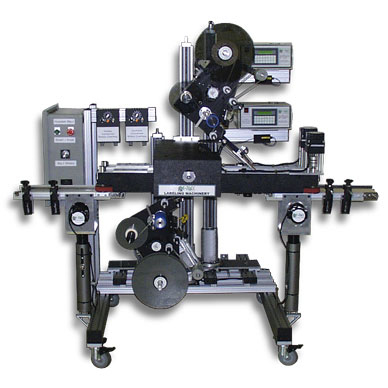

At Griffin-Rutgers, we offer three different types of tamper evident labeling systems from Accutrak. The T.E. 80 is designed to apply tamper evident labels at speeds up to 80 ppm; the T.E. 150, 150 ppm; the T.E. 250, 250 ppm. All three of our tamper evident labeling systems can be supplied with one, two, or three label applicators. The applicators can be mounted in any combination of either top or side. The basic frame of the system is the same as on our standard Accutrak Front and Back Labeling System. The base is modified to allow for a wide variety of applicator mounting arrangements, fold tooling, and wipe down devices. Many options are available for this machine including alarm packages, inspections, and verification devices. Please contact us for more information on this or any of our other products.

Most consumers are aware that there are products generally manufactured by one company but labeled with another company’s brand, aka private labeling. Not only is this beneficial to the manufacturer who profits from the sale of its product but also creates a stream of revenue from the reseller. Meanwhile, the store who is rebranding it...Continue reading→

There are many different styles of hardware supply packaging and labeling. Even with the different packaging types, it’s imperative that all your packaging meet a highly regulated set of stringent packaging regulations. Barcodes, sensor codes, warning labels, all must meet retail and wholesale standards – every single time. For instance: Nails – packaged in tubs,...Continue reading→

According to a study conducted by OnePoll, 75% of those who responded, noted that if the term ‘organic’ was used on the label or in the marketing campaign, they were more likely to make a purchase of said item. Nearly 60% were attracted to any given item if it was labeled ‘all natural’. The survey also found that roughly 20% of the respondents have full trust in organic food labels, with less than 60% having only partial trust.Continue reading→

In 2018, product packaging gave manufacturers a lot of innovative ideas and options, both functionally and aesthetically. 2019 promises to be just as innovative, and continue to grow with more color, graphics and material in exciting new ways.Continue reading→

The world of labeling changes at an ever more rapid pace every day. The professionals from Griffin-Rutgers know this because manufacturers are constantly redesigning packaging components, seeking commonality of goods, and packaging lines for greater efficiency and output. Packaging systems have to keep up with such needs for ever increasing efficiency as well as new...Continue reading→

This article possibly should be titled, “Getting to the bottom of your product is a challenge.” It’s overly simplified to say the bottom of something is the bottom because it’s standing on that surface, but that’s exactly the problem – access. Bottom labeling, or coding, requires clear access to the bottom. That’s it. Systems for...Continue reading→

Manufacturing companies that need to print labels on their products need to first determine whether they need to print on the top or the bottom of the product or need a wrap-around system. As the professionals at Griffin-Rutgers explain there are automatic labeling systems to address each print type. Griffin-Rutgers carries a complete line of...Continue reading→

Re-Pack three roller indexing labeling systems are those designed to “orient a cylindrically shaped item and apply a wrap-around label.” In this labeling process, the label application is accurately aligned to a specific spot on the individual product item. This unique labeling process can be accomplished with a fully automated, in-line system or as an...Continue reading→

The Indexing Starwheel Labeling system manufactured by Re-Pack is one that is designed to easily integrate with an existing conveyor line system. An indexing system such as this is normally used when a label needs to be placed on the bottom of a container after the filling and capping stations. Containers such as jars, tubes,...Continue reading→

If you walk into a grocery or department store and check out the baked goods section, chances are you will look at the labels and the ingredients and some of the other packaging that those products come in. More and more consumers read labels for sugar, sodium and calories along with gluten-free, GMO information and...Continue reading→