Packaging has changed quite a bit over the past few years. Clear packaging, like blister packs and clamshells are becoming a popular choice among manufacturers today. Some studies suggest that shoppers are as much as 400% more likely to pick up a package if they can see the product that is inside.

While packaging has changed, the need for clearly printed information hasn’t changed. Griffin-Rutgers will work with you to choose the precise coder and printer to ensure the accuracy of coding and labeling on blister packs and clamshells in accordance with your manufacturing specifications.

While packaging has changed, the need for clearly printed information hasn’t changed. Griffin-Rutgers will work with you to choose the precise coder and printer to ensure the accuracy of coding and labeling on blister packs and clamshells in accordance with your manufacturing specifications.

A “clamshell” pack is a fully plastic shell sealed at the edges. It’s one of the most robust retail packages. It’s good for very heavy products, and you do not need to seal a card to a blister, the card is trapped inside the clam. They are very secure from a pilfer-resistance perspective. More and more often, they are being used for small electronic devices. The inaccessibility of the packaging deters theft. Clear plastic clamshells are a popular item for packaging everything from fishing lures to thumb tacks. They are a great choice for merchandizing items, so the consumer knows exactly what they are buying

A “trapped” blister pack has a front and back card with a blister trapped between. The package presents a clean look. A well-designed, easy-open die-cut in the back of the card is often used to make the packaging easier to open. This format is good for heavier products to ensure that the blister stays fixed to the card through shipping and handling.

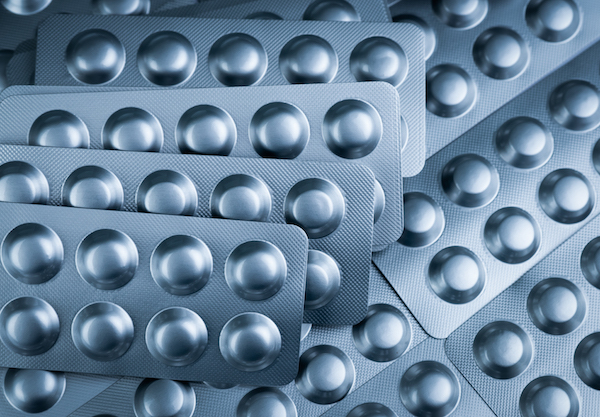

A blister pack, also known as a push-through pack typically has a perforated foil base attached to a plastic dome. These usually encase pills or capsules to protect them from moisture and tampering. On the back of the aluminum foil is where the consumer sees the information related to the specific pharmaceutical. Blister packaging is an inexpensive option for creating packages that are durable, transparent, and tamper proof.

Blisters are also commonly used on non-perishable, consumer product packages, such as cosmetic packages - which enable the consumer to see the contents, as they hang from peg hooks, in the retail stores.

No matter if you are using blister packaging or clamshells, to discuss your particular needs contact Griffin-Rutgers and let us put our experience in providing printing, coding and labeling solutions for packaging to work for you.

Foenix Printer Features The market is flooded with various models of ink jet printers across a wide range of technologies, brand names and ink types, which can make it challenging to discern what printer is the best for which application and environment. Many in the industrial and commercial marketplace are loyal to Foenix Coding Printers,...Continue reading→

Candy comes in many forms, shapes and sizes but the common factor is that they all need to be packaged. The package, as it comes down the assembly line, needs to be identified - marked, coded or printed on - and candy is packaged in a variety of substrates.Continue reading→

If the barcode or marking of your product is unreadable, it can result in recalls, unhappy customers, and even fines. It is important to identify these issues early by implementing regular checks and verification to ensure quality.Continue reading→

Medical aluminum foil is the material sealed onto a plastic film. The advantages of using this type of seal is that it is non-toxic, corrosion resistance, heat resistant, moisture and light resistant, and resistant to high-temperature sterilization. The typical thickness is usually 0.02 millimeter, consisting of a protective layer, printing layer, base material, and an...Continue reading→

Food safety is paramount for egg producers. The ability to effectively communicate traceability data and important information helps ensure producers are in compliance with safety regulations.

Growth of international free trade and inadequate drug regulations have led to the expansion of trade in counterfeit drugs worldwide. Technological protection is seen as the best way to avoid this problem. Different technologies came into existence like overt, covert, and track and trace technologies.

The food and medical industry seem to change and grow daily. With that, comes stricter package labeling being required by the FDA. It’s important that your packaging meets the demands of the ever-changing industry and its regulations. At Griffin-Rutgers, we have a solution to meet your labeling requirements.

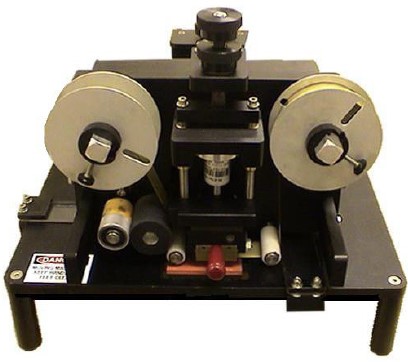

If you are printing best-before or other fixed or variable information onto sleeves, pouches or cartons, an offline feed and coding system could be just what you need.

Improvements in technology are seen everywhere in the workforce and in consumer products and packaging. Laptop computers that used to be rather weighty now seem featherweight. Innovations in packaging also continues to grow at a steady pace. The automation of horizontal packaging allows your business to run at a more efficient rate and be able...Continue reading→

In every industry, the trend for more eco-friendly packaging is taking an upturn. We are seeing that trend even in the cosmetic industry. When one thinks ‘cosmetics’ it brings to mind makeup, but, the cosmetic industry encompasses more than just eye shadow and blush. It includes everything from toothpaste to lipsticks. As such, it needs...Continue reading→

While packaging has changed, the need for clearly printed information hasn’t changed. Griffin-Rutgers will work with you to choose the precise coder and printer to ensure the accuracy of coding and labeling on blister packs and clamshells in accordance with your manufacturing specifications.

While packaging has changed, the need for clearly printed information hasn’t changed. Griffin-Rutgers will work with you to choose the precise coder and printer to ensure the accuracy of coding and labeling on blister packs and clamshells in accordance with your manufacturing specifications.