Date coders have a valuable role to play in the food industry in terms of food and food safety information

on every package that holds food products or on every label in which this information is included. Beyond this primary purpose, there are some other things you should keep in mind about these printing machines.

Decoding Date Coders

Keep in mind that the roles these food industry devices play for the food, grocery, and hospitality industries include:

- Bulk Worker: These devices are a great way of quickly and effectively labeling large quantities of proportioned food or individual food packages that must be produced and shipped in bulk measure. Machines are constructed for industrial use so that they withstand high print volumes over an extended time period.

- QC Specialist: The information must be printed clearly and accurately to protect the health and safety of the consumers or businesses that purchase that packaged food. This means that all information must be legible and maintain its integrity so that temperature changes, humidity, or human contact does not compromise the readability of the date information. These machines often provide high resolution capabilities to ensure that writing is clear and that the date stands out.

- Placement Expert: Placement of information that states when food must be sold, consumed, or discarded by must be carefully thought out. A data coder needs to be able to print on labels or packages in a safe spot where this crucial information does not get lost or torn off due to tampering or after the package is opened and partially used.

- Labor Reducer: Automating this type of labeling process saves on labor costs, creating a sustainable process for ensuring food safety enhancements on all products. Even hand-held date coding devices allow kitchen or storage staff at a food facility to quickly mark all food products that arrive with important dates.

- Multi-tasker: These devices can mark one line of information or they can do double duty by marking two lines, multiple lines of information or logos.

In Summary

A date coder works in many different ways to ensure food safety standards and help the restaurant, grocery store, or consumer keep track of the food’s freshness and window of safety wherein the food is safe to eat. Remember these highlights about this valuable piece of equipment:

- As a workhorse, it can handle large quantities of packaging over an extended period of time.

- As a quality controller, it can offer high resolution to ensure the sell by, use by, or dispose by date can be clearly read.

- As a location advocate, it can select the optimum place on a package so that the date remains in clear view until the product is used up or disposed of.

- As a labor reducer, it does more of the work to minimize the costs of staff handling such a time-intensive process.

- As a multi-tasker, it can handle and print multiple lines of information or logos .

When looking for a digital, variable data coding system to invest in and depend on, it’s important to first get to know the various system manufacturers and learn how their product offerings can help you achieve your business objectives. One of the more popular coding brands today is the SmartDate family of coders. Here are five things you should know about this particular system.Continue reading→

If you are looking for a thermal transfer printer, look no further than the SmartDate Thermal Transfer Coder as it has everything you need and quite possibly more. Not surprising given the company behind the SmartDate is MARKEM, a trusted industry leader in ink and thermal printing technology.Continue reading→

Food safety is paramount for egg producers. The ability to effectively communicate traceability data and important information helps ensure producers are in compliance with safety regulations.

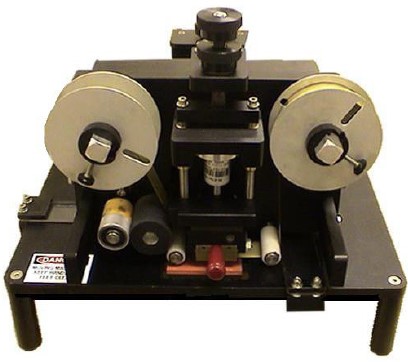

If you are printing best-before or other fixed or variable information onto sleeves, pouches or cartons, an offline feed and coding system could be just what you need.

A date coder is a printing device that adds variable information either directly onto a product, the label or to the packaging of the product. Date coding or Variable information printing can be of many different varieties ranging from a simple Production Date, Batch Number and Expiration Date to a complex 2 dimensional high density...Continue reading→

Since the inception of thermal transfer overprinters (TTOs) in the early 1990’s, Griffin-Rutgers has been there. That’s why we know that all TTOs function in the same manner, based on the identical operating principles – energize the print head, heat the ink on the mylar carrier, and with a little head pressure leave an image...Continue reading→

In recent years, pre-packaged meals have received bad press for those who are seeking a healthier lifestyle and who are turning their attention toward off-the-shelf choices. Manufacturers understand this and have been making their foods with healthier ingredients, lower sodium, fewer preservatives and in increasingly smaller packaging. The reason these meals remain popular is because...Continue reading→

Keeping your production line on-line is a top priority; when it’s down, it’ll most certainly means lost revenue and possibly adversely affect your reputation. Most of the time, there is not just a sudden breakdown but signs over a period of time that things are not functioning property. For one, knowing what to look for specific to coder machine maintenance can save you time and money down the line and ensure that you stay up and running.Continue reading→

A date coder plays an integral role in many types of product-based businesses, and it could be very beneficial to yours. This, of course, will depend on any specific industry requirements and particular products you are packaging. Here we break down what a date coder is and what advantageous this type of machine can provide for your business.Continue reading→

As the regulatory environment continues to expand to ensure that healthcare services provide safe, secure, and confidential packaging, specialized packing and coding solutions are coming to market to address those needs.Continue reading→