When looking at the available carton printers on the market today, it is important to select one that meets all of your criteria. High resolution carton printers offer some significant advantages, making them worth serious consideration.

Top Benefits of Going High Resolution

Here are four advantages of selecting from this technology of carton printers:

- Excellent Print Images: They can print high quality graphics, logos, barcodes and 2D codes in the same message. Offering excellent print images and aesthetics is the top advantage. These printers can handle very complex and detailed images, delivering a crisp and clear presentation that helps sell the carton products or market the company brand it represents.

- Flexibility: Today’s packaging often requires changes due to regulatory measures, customer needs, and the expansion of product lines. Therefore it helps to have one printer that can do it all and handle it all, rather than being faced with a new investment in additional equipment. High resolution carton printers are designed to work with various carton substrates, sizes, shapes and can handle a variety of printing demands.

- Durability: With many companies facing shorter lead times and high volume delivery requests, there is no room for downtime. That’s why it’s good to consider a well-designed, quality, high resolution printer for your carton printing, because it goes the distance. Additionally, these types of machines are scalable in their capacity, being able to take on more and more as demand grows.

- Accuracy: There is no margin for error when it comes to printing cartons. Information printed on the carton – whether it is a logo, illustration, bar code, or sequential numbering – has to be done correctly the first time or it will create a logistical nightmare for a business. A high resolution printing system for cartons is built with accuracy in mind and user-friendly capability to work with increasingly complex and variable sets of data that cartons now require.

In noting the highlights from this article on the benefits found in high resolution printers for cartons, remember these key points:

- Advantages are delivered across all aspects of the carton printing process.

- High quality print images and precise barcodes are critical with emerging data requirements. A quality image and presentation reflects on the company’s reputation and paints a good picture about what that firm offers.

- Trends and demands are in constant flux, so it is important to have equipment that can adapt with the times rather than to be stuck with a system that has to be upgraded or changed.

- These machines are simple in their design, easy to use and built to last.

Growth of international free trade and inadequate drug regulations have led to the expansion of trade in counterfeit drugs worldwide. Technological protection is seen as the best way to avoid this problem. Different technologies came into existence like overt, covert, and track and trace technologies.

High resolution printing is simply not what it used to be. Advancements in technology have ensured that the printing industry can offer the best in quality, no matter the application, style or needs of the client. Of course, with better printers and higher resolutions, the need for a greater quality of ink must be at...Continue reading→

Needham Coding is a leading global manufacturer and supplier of state-of-the-art high resolution ink jet printers for the packaging industry. For almost 60-years, Needham Coding has been on the cutting edge of package identification, now using its own research and development department to advance ink jet technologies. Indeed, the company’s line of printers are revered...Continue reading→

The Needham S-6000 series is a great alternative to CIJ (Continuous Ink Jet) due to its ease of use and simplified maintenance benefits.Continue reading→

When seeking a top-performing printer that can effectively deliver quality coding and printing on corrugated boxes, cases and trays, look no further than the Needham S-6000Plus. This best-of-breed ink jet machine utilizes the latest technology to provide online, high resolution capabilities that work for everything from small and large characters to bar codes and graphics. Continue reading→

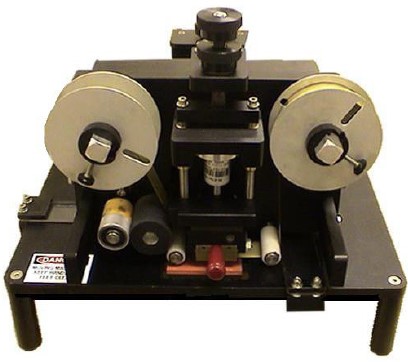

If you are printing best-before or other fixed or variable information onto sleeves, pouches or cartons, an offline feed and coding system could be just what you need.

Accuracy and speed are crucial in all aspects of printing and labeling and this is especially true in the pharmaceutical field. Pharmaceutical packaging and labeling are required to comply with state and federal regulations as well as meeting specific manufacturer and industry requirements. Many pharmaceutical carton and case printing needs can be accomplished with automatic...Continue reading→

If you are a manufacturer that works with folding cartons, you have no doubt been faced with the issue that this type of container poses for your coding and marking procedures. You understand that the variable data that needs to be applied to a carton is only one element of the entire production and printing...Continue reading→

Carton Coding machines have numerous usages but pharmaceutical carton printing has created an industry based on the benefits of offline carton coding. Because pharmaceutical cartons are many times constructed a specific way, they create a high demand for offline machines. Often, pharmaceutical cartons are used for the packing of multiple packs, labeled erect and put...Continue reading→

When the holidays roll around, how can you set your product apart from the others that crowd the shelves and vie for your customer’s attention? One way is through the use of festive sleeves for your products. Food products effectively lend themselves to festive sleeves or cartons and with eye catching packaging you may see...Continue reading→