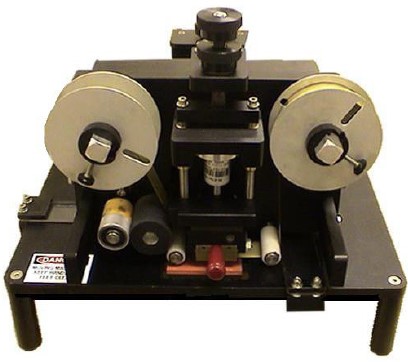

When it comes to your hot stamp date coder, there are times when it might operate improperly—not unlike other types of equipment utilized for a high-demand production schedule. Better assuring the maximum performance from your date coder involves understanding the mechanics of proper work function so that you can discern when an issue is at hand. But, there are a few distinct problem signs to look out for. Here are three signs indicating that your date coder is not operating properly:

- No print on material: The causes here could relate to a printing block that is not installed, a print head that is not properly heated, or too large of a distance between the printing block and the imprint material. The machine’s manual or technical support can help the operator with installing the printing block as well as adjusting the printing distance. Service personnel should also be able to help with checking the print head temperature with a pyrometer and making the necessary maintenance adjustments.

- Print cylinder does not move: There could be many reasons for this – from something as simple as the machine not receiving power, to an incorrect amount of compressed air supply or an abbreviated print time that must be adjusted. The first step is to check that the machine is on and the power source is functional. The compressed air supply may also need to be turned on. To increase the print time, the manual for the machine can show the operator how to adjust as needed.

- The print result is not satisfactory: There can be numerous reasons why this date coder operation fails, including too large of a distance between the print block and the material to be printed, low air pressure, low print temperature or short printing time. Other reasons include the fact that the print unit is printing on a section of the stamping foil that has already been used or be a fault in the advanced direction of the stamping foil so that it does not advance properly. Also that the product has a coating or varnish that rejects the transfer of the ribbon ink to it or the ribbon composition is not properly formulated for the surface of the item to be printed. Corrective actions include assistance from service personnel in charge of maintaining the machine, following operation instructions from the machine’s manual, or a conversation with the hot stamp ribbon supplier thereby alleviating any and all of these causes.

In Summary If you want to ensure that your hot stamp date coder is working at its peak performance, you need to be familiar with the following three signs:

- There is no print on the material because of a missing printing block, an improperly heated print head, or too much distance between the printing block and the material that needs to be printed.

- The print cylinder does not move because it is not receiving power, there is not enough compressed air supply, or the print time is too short.

- The print result is not satisfactory because of too much distance between printing block and material, low print temperature, low air pressure, shot printing time, stamping foil that has been previously been used is being used again, the stamping foil does not advance properly- or it could be in the relationship between the item to be printed and the hot stamp ribbon.