Griffin-Rutgers labeling and coding systems are well suited for the pharmaceutical industry. Manufacturers and packagers of pharmaceutical products understand that a product identification system for pharmaceutical packaging requires two separate, but highly integrated components. It is mandatory to have a coding/labeling system that can consistently print in high resolution and apply labels at the required speed with a high degree of accuracy.

Some of these types of packaging can be: pharma blister packs, pharma/medical device cartons, dietary supplements pouches, nutraceutical bottles, along with cannabis tins. Staying current on the regulations in the industry is challenging, but having a printing and labeling system in place that helps adhere to them is key to any operation.

At Griffin-Rutgers we understand the never-ending demand for consistent, accurate labeling, along with the need for print clarity and product tracking mechanisms throughout the packaging and distribution chain. As you consider the purchase, we can help you determine the best product identification (labeling and coding) system for your unique needs. Contact the professionals at Griffin-Rutgers, and we will put our experience to work to select the exact system for you.

Dalemark Series 200 – Heavy Duty Conveyor Printer

The Series 200 HD is of such exceptionally rugged design that it is optimal for any carton, case or tray coding application or environment. It is ideal for date, batch or logo printing on almost any top, bottom or side moving surface. Its design even allows for printing on uneven or bulging surfaces. Inks are […]

Markoprint X2Jet

HP or LX print system with onboard label creation and editing. Runs 2 HP or LX print heads

S-6000 Plus Standard and Duo

The compact S-6000 Plus Standard is perfect for identifying cartons with printing up to 17mm high text and bar codes while the Duo allows for printing up to 34mm high characters. The 17mm high print heads are available with manual or motorized print head shutters.

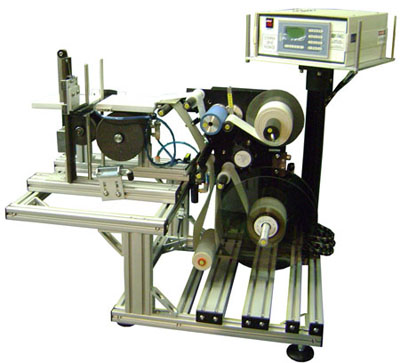

Re-Pack Mini Panel Labeling System

Entry level offering that can be equipped with the majority of the options from our Open Frame Series of labelers

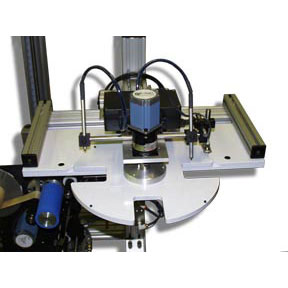

Rotech RF1

Vacuum transport system using either thermal ink, jet, thermal transfer , hot stamp or laser coding systems

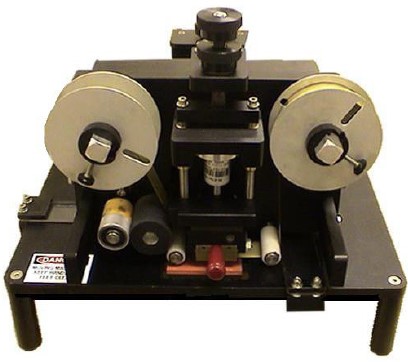

Is There A Solution For Serialization?

Is There A Solution For “Serialization” that doesn’t require complete production line shut down to accomplish integration? There are off-line systems that have been developed that can feed, transport and print data matrix codes onto cartons that are in a flattened form. These off-line systems have been supplied to pharmaceutical customers worldwide and are manufactured […]

Coding And Labeling On Blister Packs And Clamshells

Packaging has changed quite a bit over the past few years. Clear packaging, like blister packs and clamshells are becoming a popular choice among manufacturers today. Some studies suggest that shoppers are as much as 400% more likely to pick up a package if they can see the product that is inside.

Offline Coding Leads To Compliance

Pharmaceutical manufacturers and packagers could be facing increased costs due to re-engineering of production lines to satisfy newly upgraded European Union Falsified Medicines Directives (FMD). Printing and packaging systems that carry out coding, and its related post-print inspection, offline as an independent process might make it easier for manufacturers to meet the new compliance requirements […]

Stricter Package Labeling Being Required By The FDA

The food and medical industry seem to change and grow daily. With that, comes stricter package labeling being required by the FDA. It’s important that your packaging meets the demands of the ever-changing industry and its regulations. At Griffin-Rutgers, we have a solution to meet your labeling requirements.

What Do Pharmaceutical Carton and Case Feeders Do?

Accuracy and speed are crucial in all aspects of printing and labeling and this is especially true in the pharmaceutical field. Pharmaceutical packaging and labeling are required to comply with state and federal regulations as well as meeting specific manufacturer and industry requirements. Many pharmaceutical carton and case printing needs can be accomplished with automatic […]

Pharmaceutical Labeling Requires Specialized Printers

Manufacturers and packagers of pharmaceutical products understand that a product identification system for pharmaceutical packaging requires two separate, but highly integrated components. It is mandatory to have a labeling system that can consistently apply labels at the required speed and with a high degree of accuracy. Along with such a labeler packagers need a print […]

Five Reasons To Choose An Offline Coding System

If you are printing best-before or other fixed or variable information onto sleeves, pouches or cartons, an offline feed and coding system could be just what you need.

Increased Packaging Regulations Lead To System Overhauls

Stricter regulations that will aid in the fight against counterfeit drugs are leading a good number of pharmaceutical companies scrambling to meet the new compliance regulations. In order to do so they are looking at the potential of overhauling not only the packaging, but the distribution and tracking systems in place for all of their […]

Pharmaceutical Track and Trace Problems Resolved With TraxSecur™

When H.R. 3204, The Drug Quality and Security Act was passed, many organizations had to rethink the way they label and track pharmaceuticals to be in compliance. The bill was designed to clarify laws related to human drug compounding and to strengthen the prescription drug supply chain in order to defend against counterfeit drugs. A […]