This article possibly should be titled, “Getting to the bottom of your product is a challenge.” It’s overly simplified to say the bottom of something is the bottom because it’s standing on that surface, but that’s exactly the problem – access. Bottom labeling, or coding, requires clear access to the bottom. That’s it.

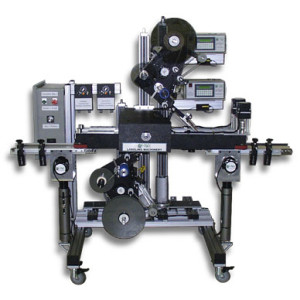

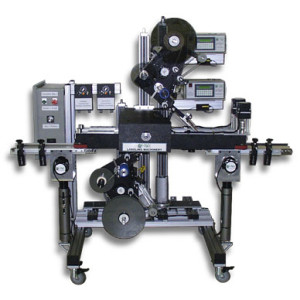

Systems for products that require identification on the bottom surface consist of a support “platform” of some sort with the labeling head or coder mounted on the bottom. The product upon which a label or code is needed will be drawn into the system and the label or code will be applied.

For conveyor transported items being moved in-line, assuming that an operation cannot turn the product over and label or code from the side or top then, a clever means of reaching the bottom has to be found. Size and shape of the item to be identified will determine the approach necessary to gain access to the bottom for printing or label application. For long items (8 foot long pieces of flooring trim) that can span an opening and remain stable and upright, then a simple gap between two co-speed conveyors can suffice. But a small jar can’t usually span an opening and remain standing. For those products where vertical stability is necessary a co-speed set of side “hugger” belts can grab an item from both sides and transport it forward through a labeling system or coding device. Since the hugger belts capture and hold the product from the sides this also leaves the bottom, top, front and back of the container exposed for label application. So not only is the hugger belt system is ideal for small products that are too unstable to. transport without support, it also is ideal when multi-panel labels are required to be wrapped around multiple product surfaces.

For operations that have lower product throughput needs, semi-automatic systems exist that can address the need for labeling and coding on the bottom. Semi-automatic labeling and coding systems are traditionally hand loaded devices that allow the operator to manipulate the product making access to the bottom a much easier problem to solve.

Whether your manufacturing needs require coding or labeling on the bottom of a product, either in-line on a conveyor or off-line with a semi-automatic device, Griffin-Rutgers has a system that will suit every need. A bottom labeling or coding system can be configured to handle bottles or jars, cartons or trays and can apply codes or labels to virtually any shape of product.

Bottom labeling systems are used for a wide variety of package types in a wide range of industries such as the following:

- Automotive

- Beverage

- Electronics

- Healthcare and pharmaceutical

- Medical devices

Talk with the professionals from Griffin-Rutgers to assure you invest in the correct system to cost effectively fulfill your unique needs. Reach us at 1-800-237-6713 or custserv@griffin-rutgers.com.

Whether you’re a first year start-up, a larger company that has only a small need for high resolution printing or a company that has a large need for high resolution printing there’s a good chance you’re looking for a low-cost way to code your packages. But, of course, you still want to look professional in...Continue reading→

Foenix Printer Features The market is flooded with various models of ink jet printers across a wide range of technologies, brand names and ink types, which can make it challenging to discern what printer is the best for which application and environment. Many in the industrial and commercial marketplace are loyal to Foenix Coding Printers,...Continue reading→

The number of babies expected to be born in the next year is less than usual due to the coronavirus problem. However, there are still many babies who need baby bottles and nipples to fulfill their feeding needs.Continue reading→

Studies have shown that 65-70 percent of purchase decisions are made in-store based on the product packaging and labels alone. With the vast quantity of products available, product packaging is incredibly important! Whether you’re redesigning the look of your existing packaging or launching a new product, there are several tips that will help you produce...Continue reading→

Most consumers are aware that there are products generally manufactured by one company but labeled with another company’s brand, aka private labeling. Not only is this beneficial to the manufacturer who profits from the sale of its product but also creates a stream of revenue from the reseller. Meanwhile, the store who is rebranding it...Continue reading→

There are many different styles of hardware supply packaging and labeling. Even with the different packaging types, it’s imperative that all your packaging meet a highly regulated set of stringent packaging regulations. Barcodes, sensor codes, warning labels, all must meet retail and wholesale standards – every single time. For instance: Nails – packaged in tubs,...Continue reading→

Consumers are becoming more savvy with regards to their food choices and many are turning to vegan, or plant-based alternatives. While it may seem these terms are interchangeable, as they both exclude animal products, they are not necessarily viewed the same way, says the Plant Based Foods Association (PBFA). Labels on vegan or plant-based products...Continue reading→

The demand for electronic cigarettes is on the rise and is showing no sign of slowing down. Without a doubt, ‘vaping’, as it’s commonly called, is gaining popularity. According to one survey, 10% of adults in the U.S. now vape, and the CDC indicates that more than 9 million U.S. adults vape on a regular basis.Continue reading→

According to a study conducted by OnePoll, 75% of those who responded, noted that if the term ‘organic’ was used on the label or in the marketing campaign, they were more likely to make a purchase of said item. Nearly 60% were attracted to any given item if it was labeled ‘all natural’. The survey also found that roughly 20% of the respondents have full trust in organic food labels, with less than 60% having only partial trust.Continue reading→

If the barcode or marking of your product is unreadable, it can result in recalls, unhappy customers, and even fines. It is important to identify these issues early by implementing regular checks and verification to ensure quality.Continue reading→